Time is of the essence when it comes to making new products or parts. Whale-Stone provides a quick prototyping service for wholesale buyers, who only take a second to turn their concepts into real-life greetings. Onion 3D can transform your ideas in to physical prototypes as quickly as possible with our high end 3d printer stereolithography prototyping services. Whether it is the automobile industry, electronics or any other sector, you can count on our team of experts to help you remain innovative and ahead from your competition.

Stereolithography prototyping is an innovative way to transform how businesses prototype. What are the Added Advantages of Our Whale-Stone 3d printing rapid prototyping and Consultancy Services? A key benefit is the quick production of prototypes. Stereolithography lends itself to complex design that can be generated in hours, not days, and rapidly iterated on. This can help your business save a lot of time and money in the product development.

What’s more, stereolithography prototyping is budget-friendly for both small and large businesses. With this innovation you can escape the hefty expenditure of conventional fabrication processes that includes tool and die manufacturing. This makes prototyping achievable for small businesses and start-ups, allowing them to compete with bigger business in the industry.

Just one of the reasons our prototyping services are not like the other guys is our dedication to customer satisfaction. We have ended up close relationships with the clients all over the world, and we grow together. Our custom Whale-Stone stereolithography prototyping aspect separates us from the other prototyping businesses, that neglect to provide your business with the same close attention and consideration.

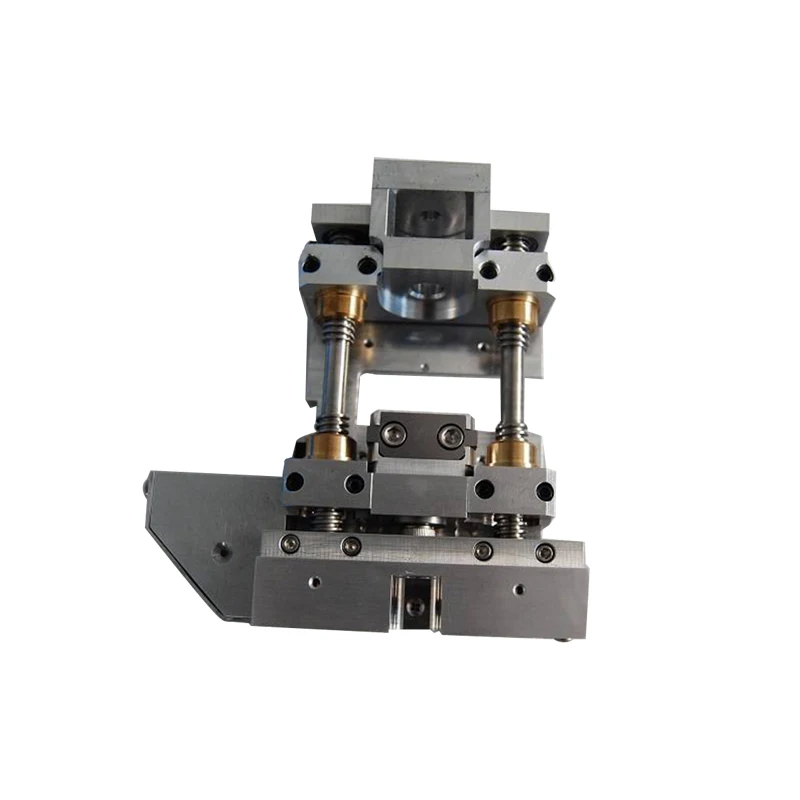

Our advanced machinery and technology also allow us to stay ahead in the industry. We make sure we invest in the most current stereolithography machines and software, so that we are able to deliver models with the best quality possible. In turn, this enables us to offer high-quality and high-accuracy prototypes that outstrip other prototype service companies.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.