Metal laser printing is a state-of-the-art new technology that is transforming what's possible when it comes to creating and customizing metal products. Whale-Stone is leading the way in this exciting development, providing superior quality laser etching for different metallic materials. Whatever material you're working with, including stainless steel, aluminum or any other type of metal, we are your professional source for laser engraved plates. Let’s examine further how metal laser printing can improve the durability quality of items while at the same time supplying customization for a range of applications

Metal laser printing can be customized to reflect your unique personality. Our high quality laser printing technology allows us to reproduce the finest details, logos and patterns in metal with extreme precision. Whether you’re looking for a company logo inscribed on a stainless steel plate Work with The Best Looking to have a custom design printed onto an aluminum part? Since laser printing is incredibly precise and detailed, no two metal products are identical when they're created. Printing on balls with laser is also fast perfect for small and large order printing.

One great advantage of the metal laser cutting is that it gives products a longer life product durability. Laser cutting our designs into metal means we can create a design which will last - and wont wear away. Not like inks which can fade, flake, or crack over time; Laser printing lets you design your heart out and it stays put as long as silk does! It's this kind of durability that makes laser cut metal products perfect for anything where long-lasting quality is essential, including aerospace, the automotive industry and medicine. Whale-Stone will give you the assurance that your metal products remain eye-catching for many years to come, even in the most challenging conditions with laser printing

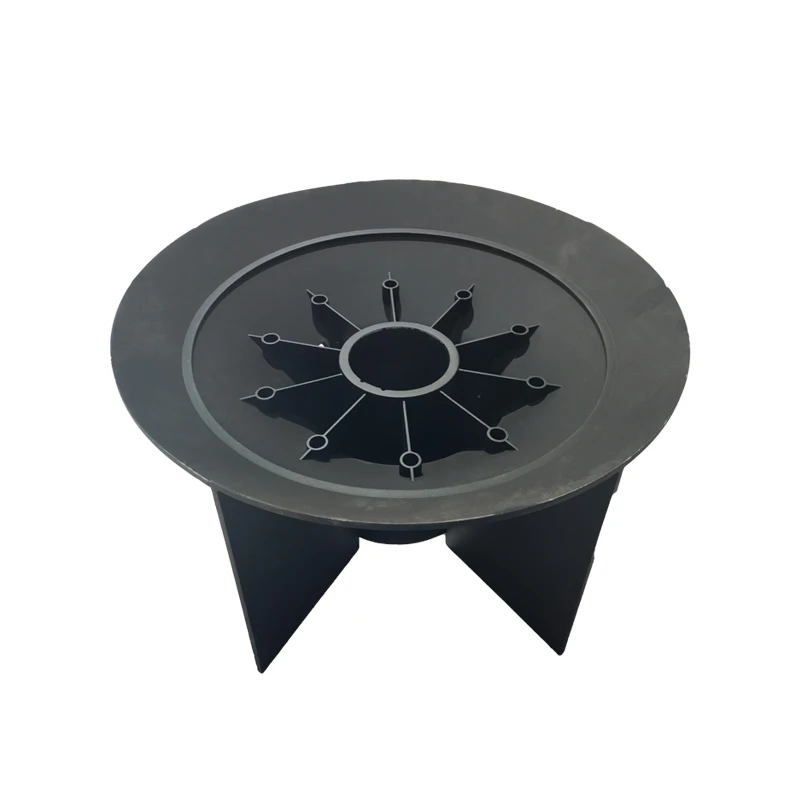

Metal laser printing is a state-of-the-art process that brings many advantages to metal manufacturing. A key benefit of laser printing is its accuracy. The use of laser sintering 3d printing to engrave the metal is the most efficient and precise way, and ensures every go will look just as good as expected. This precision also enables the use laser printing to produce very detailed patterns and designs that would be difficult or impossible with conventional methods.

Durability is another of crucial advantage when laser printing on metal is used. Laser-etched designs are non-toxic, non-stick & environmentally safe and there are no chemical dyes involved with the process. The laser designs produced in this way will not wear out The etching is permanent. Furthermore, laser sintered metal 3d printing is an inexpensive method of fabricating metallic Article 1, since the costs associated with expensive forming and tooling properties are eliminated.

For the past few years, the use of a laser printer has become increasingly common in crafting on metal. One of the current fashion trends is geometric patterns and shapes, which can be easily achieved using laser technologies. These designs are clean and modern - ideal for a variety of spaces whether adding to paper goods or home decor or even automotive settings!

In metal fabrication, Slm laser printing is preferred due to its many benefits that allows it to be the ideal choice for several applications. Here are some reason for choosing lampa laser. Designs can etched onto many metal surfaces such as stainless steel, aluminum and titanium using laser technology which makes it ideal for a wide selection of products and industries.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.