Metal 3D printing, especially laser sintered metal 3D printing, is a hot topic in the industry right now. Most typical techniques of manufacturing are time-consuming, very expensive and have strict design limitations. That is, until metal 3D printing and technologies like laser sintered came along to allow manufacturers fast, accurate, cost-effective creation of intricate parts out of metal

Laser Sintered Metal 3D Printing: Why Wholesale Buyers Are Winning In More Ways Than One One of the main benefits is the ability to manufacture complex metal parts in a short period of time. This is to say that wholesale consumers can have selective laser sintering large orders of complicated requirements filled up in a fraction of the time needed through traditional manufacturing. And with laser sintered metal 3D printing, customization can be achieved on volume level, without compromising quality and pricing by being able to offer the customized product to a wholesale buyer that needs it without having to create 10.000 custom designs or lose money on each

And lastly, laser sintered metal 3D printing makes wholesale consumers much more flexible in their manufacturing process; They can iterate models on the fly and test new concepts without incurring expensive tooling changes or time-consuming lead times. It’s this flexibility that enables wholesale buyers to know what trends are emerging in the marketplace, react promptly to customers’ needs and have a leg up on competitors

Additionally, buyers now have the chance to build greater efficiencies into their supply chains and further streamline inventory costs with laser sintered metal 3D printing. Large purchasers can reduce overstock, free up space for more profitable laser sintering 3d printing merchandise, and increase efficiency in inventory management. This lean model of cutting costs also enables wholesale buyers to make themselves more responsive to altering market needs and unexpected changes in demand

laser sintered metal 3D printing is changing the face of manufacturing for wholesale buyers. Fast, accurate, economical and adaptable, this technology is enabling wholesale buyers to simplify production, provide custom products – and remain selective laser sintering 3d printing ahead of the curve. Laser sintered metal 3D printing opens up a world of possibilities for wholesale purchasers to grow, innovate, and thrive in the manufacturing business

When it comes to wholesale orders of laser sintered metal 3D printing in china, Whale-Stone is your premier source for quality services. Boasting advanced equipment and sophisticated staff, Whale-Stone guarantees to delivery every wholesale laser sintering 3d printing order in top quality and on schedule. CommonObject’s dedication to quality and customer drive makes us a beacon in the industry, so if you’re a business wanting trusted 3D printing services – let’s work together

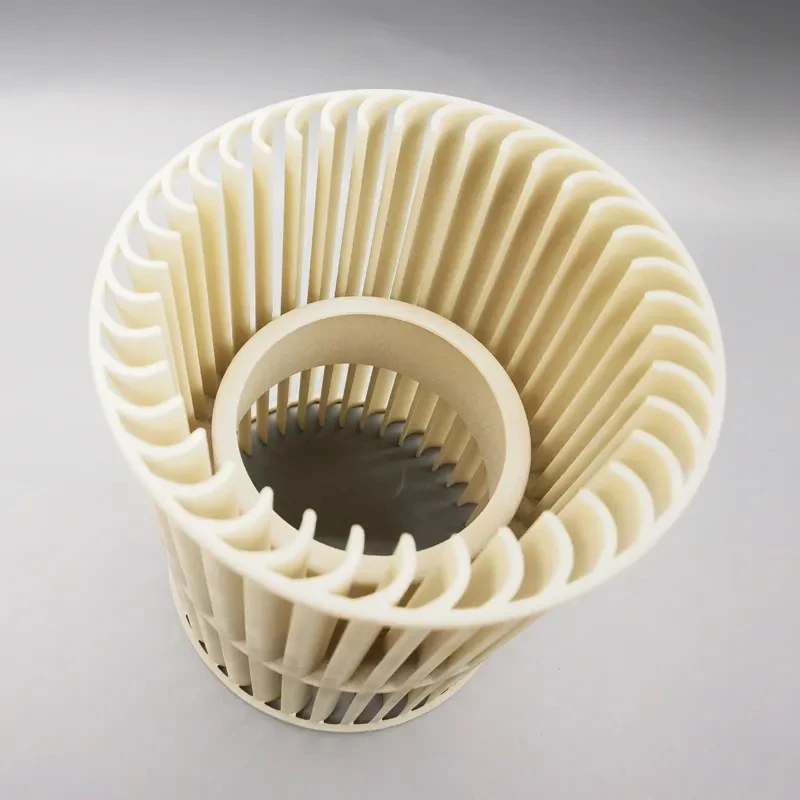

This high tech process enables very. intricate and complex laser sintering 3d printing designs to be made exactly the way it is in any size. Next, the printing time and price are not that expensive laser sintered metal 3D printing is an ideal option for wholesale orders. With Whale-Stone experience in this relield, wholesale buyers can be assured of high quality product that fulfill their needs and surpass their expectations

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.