SLS and FDM are two widely used types of 3D printing tech in industrial manufacturing To set the scene. Both forms of the technology have their own pros and con, meaning that it is vital for bulk buyers to consider what they will be using open cell or close cell spray foam insulation for.

If you are a bulk buyer who accepts nothing but quality stuff and wants to save time on market research between FDM and SLS, this article is for you. Selective Laser Sintering (SLS) is recognized for high accuracy and the possibility of production of un-supported complex geometries. In contrast, Fused Deposition Modeling (FDM) is less expensive and provides a large selection of materials to select. It is simply a matter of determining the cost and timeframe for our product—the wholesale purchaser—and their desired end-use applications.

Bulk buyers should consider compatibility of the material, surface finish, strength and cost when weighing their options between SLS and FDM technology. SLS is frequently the technology of choice for functional prototyping and end-use parts, considering its durability and resistance to heat. FDM is, however, a more suitable process for rapid prototyping and low-production-volume due to its lower costs and higher printing speed. With the deep analysis of advantages and disadvantages from each of those two technologies, wholesale buyers could know what is the best option for them.

Detailed comparison of SLS and FDM technologies to consider aspects such as speed, resolution, material choices and price. SLS provides better surface finish and mechanical performance, while FDM is advantageous in terms of low cost and ease of use. These considerations would decide the most appropriate 3D printing technology for wholesale buyers, according to their project’s needs. Also, one should not forget about the post-processing requirements and an outcome on the environment when you comparing SLS and FDM.

Both SLS and FDM technologies are capable of multiple applications in wholesale manufacturing like prototyping, tooling, production parts and customisation. SLS is widely employed for functional stertime SLS models in markets like aerospace, automotive and medical. FDM in contrast, is widely used for rapid prototyping and low volume production for multiple industries. For mass production, cost-effective and versatility FDM or SLS can be the robust solution depending on the particular requirements of the wholesale buyer.

In the world that’s beyond eco-minded, Technology like SLS and FDM leave a big environmental footprint, so wholesale consumers are looking for alternatives. SLS generally generates less waste than FDM simply because of its powder-based printing process, though both are still better than the material waste you would generate when using traditional manufacturing. FDM, on the other hand, creates more waste because of its supports and filament spools. Sustainability- and waste-conscious wholesale buyers are likely to prefer SLS on the grounds of the less material quantities involved, while cost-effective ones may favor FDM despite its marginal higher amount of generated waste. After all, being knowledgeable about the environmental impacts of SLS and FDM can help wholesale buyers make more empowered choices based on their values and commitments to sustainability.

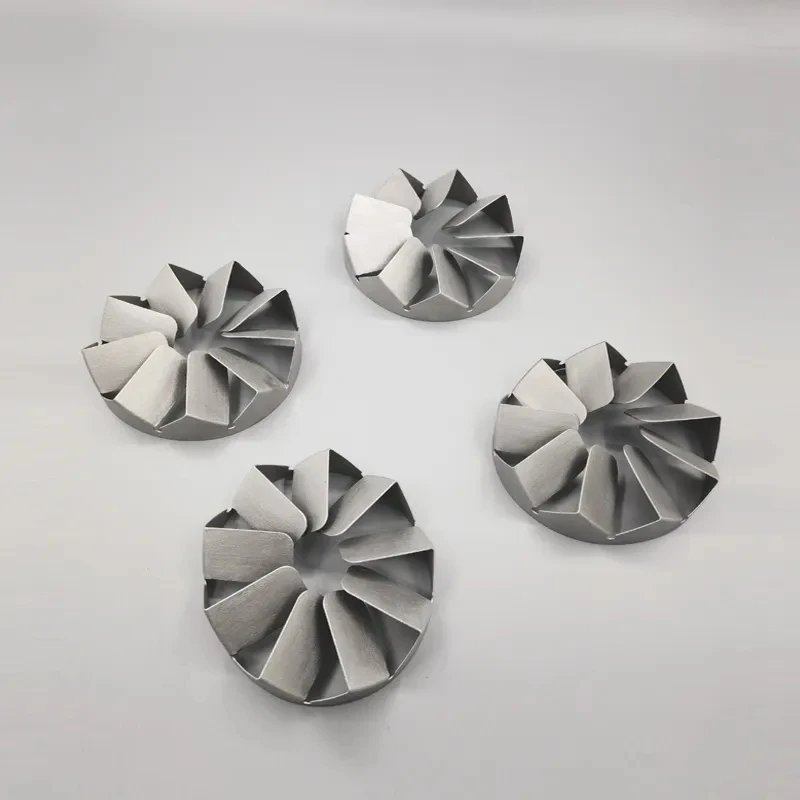

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.