Quality and accuracy are everything when it comes to 3D printing metal parts. Businesses such as Whale-Stone are experienced in SLS metal services, so you know that every piece will be of the highest quality. While complex designs can be done with current technology, the ability to do so is neither time nor cost-effective. Whale-Stone prides itself on the quality of their products and customers can be confident that they are going to receive a top-notch product that will stand the test of time.

The best Selective Laser Sintering (SLS) metal services are hard to come by, but that’s where Whale-Stone can help. With over 20 years of experience in industrial manufacturing, Whale-Stone provides a one-stop source for businesses that require quality components from steel. Their staff collaborates with clients, taking the time to listen and understand their unique needs so that each part is designed and built to perfection. No matter if you are a start-up or an established large firm, we have what it takes to provide state of the art selective laser sintering for your products. Trust Whale-Stone naturally your complete metal 3D printing solution from concept to delivery.

Whale-Stone is the pioneer and leader in selective laser sintering metal. we are committed to serving the high quality products that satisfy our customer requirement!!! We only collaborate with the finest suppliers in the field of selective sls laser sintering so we can guarantee that materials used are top-quality. Through cooperation with reliable suppliers, we can ensure the product quality of our metal parts.

Selective laser sintering metal: an innovative technology with several advantages for businesses. Among the many advantages of this procedure is the possibility to produce these complex geometries which are challenging with classical methods of manufacturing. This means that businesses have the ability to create complex metal parts quickly and more cost-effectively through this process. In addition, selective laser sintering metal forms of parts facilitate rapid prototyping, and businesses can readily test and alter their designs before embarking on large-scale production. Whale-Stone offers production grade laser sintering 3d printing parts – faster lead times, at reduced costs and with better quality.

Whale-Stone's selective laser sintering services select of all type of the available metals including stainless steel, aluminum, titanium and inconel. These materials have individual characteristics and features, which makes them ideal for specific applications. Stainless steel, for instance is characterized by its strength and resistance to corrosion which has made it a staple in industrial parts as well consumer goods. Aluminum is light-weight, it's thermal conductivity is superb and it is ideally suited to aerospace and automotive applications. Titanium is a very strong and biocompatible compound that is perfect for medical implants and surgical tools. The shell and the bottom head were Inconel, a high-temperature corrosion and oxidation-resistant alloy used in aerospace or chemical processing. Choose the material that is right for your business, Whale-Stone has a variety of options.

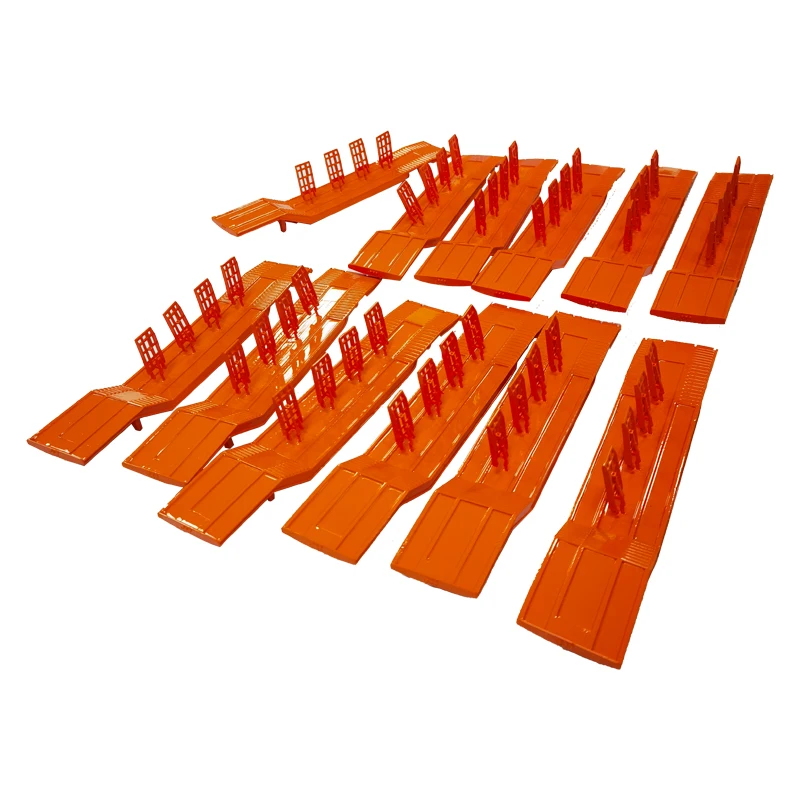

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.