Not only does SLS Stereolithography offer many advantages over other forms of 3D printing. One of the neatest things about this technology is that it can create really complex shapes that other techniques cannot handle. Think of like carving a very intricate sculpture or making something fancy with gears and doodads all over the place — that’s what Sls printing service is built for! And the prints are super smooth and accurate, so you won’t be left with any rough edges or bumpy surfaces. Whale-Stone employs the technology to develop high-quality products across a wide range of industries, from toys to tools. With SLS Stereolithography the sky is the limit!

Cutting edge technology that is redefining the way things are made SLS Stereolithography. Unlike the conventional method of manufacturing which includes injection molding or CNC, in SLS Stereolithography a laser is used to solidify a layer of resin or powder into delicate and extremely detailed parts. This method’s advantages are comprised by its ability to create complex geometries that couldn't be reached via a classical manufacturing process

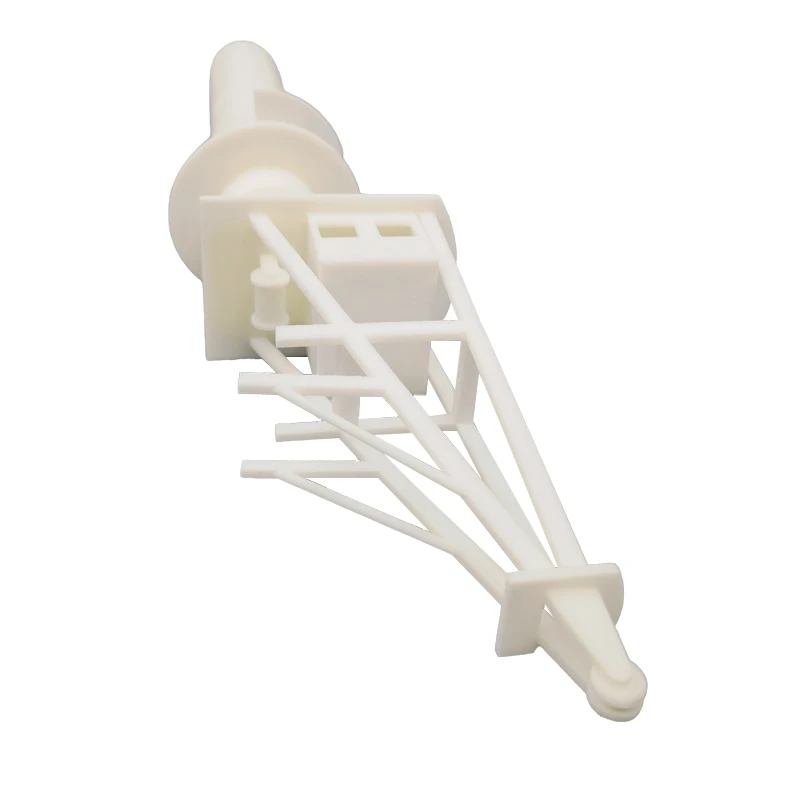

One of the benefits of selective laser sintering Sls technology is that it produces parts naturally free from support materials. This allows designers to be less inhibited by the limitations of traditional production techniques, and to push the boundaries of what is possible. Furthermore, being SLS Stereolithographs the process is extremely high definition meaning each part will be done with to the exact measurements needed.

Whale-Stone understands the value of quality and reliability in the SLS Stereolithography world. To keep up with our parts' precision and quality, we constantly upgrade our technology and machines to the latest standards. The range of production is from single off prototyping to higher volume production. Whale-Stone is capable of fulfilling any kind of request, whether it is a large or a small one.

The SLS Stereolithography process possesses several important characteristics, which differ significantly from other types of manufacturing processes. One of the major benefits of nylon Sls printing is its capacity to print parts with complicated geometry and fine details. This is therefore a perfect material for applications in aerospace, automotive and medical device construction where exactness or precision is absolutely necessary.

Another advantage of SLS Stereolithography is its speed and low cost. In comparison with other machining methods that can be lengthy due to tooling and setup, SLS Stereolithography is considerably quicker in making parts. So you can go through the whole prototyping process in a very short time and get back your work fast – a thing that companies and start-ups eager to bring products to market are most definitely fond of.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.