Nylon SLS printing is a revolutionary technology with numerous advantages for wholesale Over all else. From rapidly producing robust prototypes to on-demand production of finished parts, the ability to print what is needed for instantaneous use in any application is changing how product development and manufacturing are working across numerous markets. Read on for more benefits of nylon SLS printing concerning wholesale applications and where you can find reliable companies that offer bulk orders.

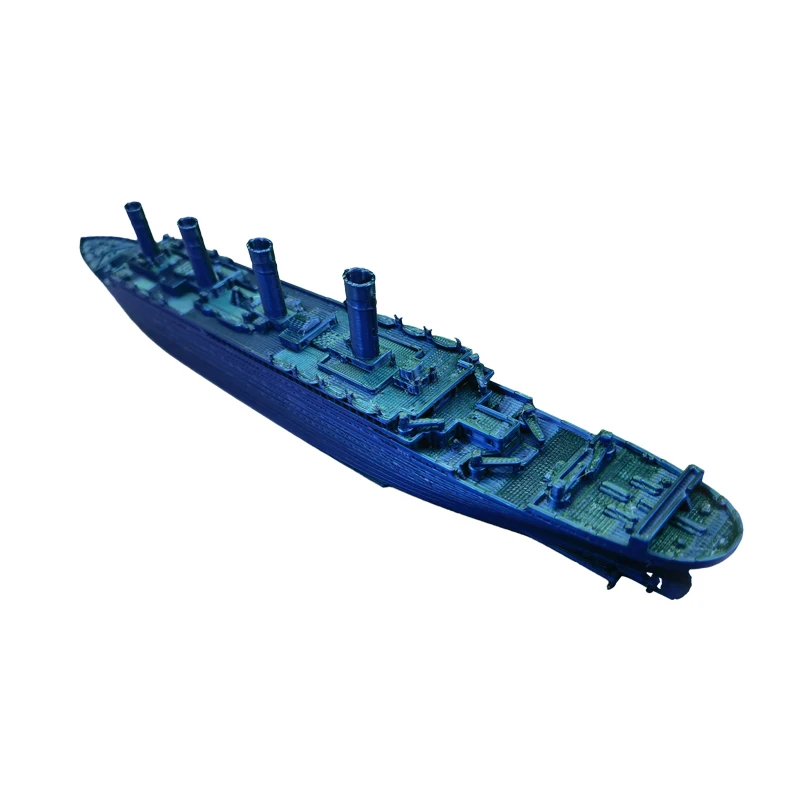

Nylon SLS 3D printing is famed for its capacity to produce complex geometries and detailed patterns that could be expensive or difficult to manufacture with traditional manufacturing processes. Rapid prototyping technologies also provide companies the opportunity to iterate and test ideas before going into large-scale changes. Furthermore, nylon SLS 3D print has superb strength to weight ratio, ensuring lightweight yet durable parts for many applications. Whether you are in the automotive, aerospace, medical or consumer industries we can help with your large-scale wholesale manufacturing needs through sls nylon 3d printing.

Also, you have flexibility of printing small batches of custom products without large set up costs which makes Nylon SLS printed models a realistic choice also for those with wholesale request. This 3D printing method also minimizes waste when compared to conventional subtractive manufacturing techniques, supporting sustainable and environmentally friendly production. Nylon SLS printing allows for quality, repeatable parts that translate to satisfied customers and return business in a world of market elasticity. Nylon SLS 3D printing is susprisingly versatile and reliable, making it a great choice for much more than just heads-up on multi-rotors.

If you are looking for a nylon SLS 3D printing service provider which can undertake this type of large-scale operation, it is important to choose an established producer such as Whale-Stone, who have the know-how and experience to offer a quality service. The industrial manufacturer and supplier committed to offering high-quality 3d printing nylon balls for wholesale. With years of experience and a staff that is well-versed in various disciplines, we provides an array of additive manufacturing part to suit the specialized needs of clients.

We invested in up-to-date factory with modern technology and machineries for high quality product, excellent precision and efficiency. If your requirement is specialized or even you need to produce a huge number of parts, we can deliver cost effective and professional service for bulk orders. With our nylon SLS printing knowledge, we can assist you to shorten your production time and maximise cost saving in large-scale productions. You can trust Whale-Stone to be your trustworthy partner offering the best in nylon SLS printing and taking your wholesale applications to the next level with creative additive manufacturing!

If you are seeking wholesale pricing for your nylon SLS print services, there are a few things that you must take into consideration to make sure you are getting the best deal. Our company has a competitive price advantage on quantity orders for nylon SLS printing, which is a good thing to select for businesses that want to save their product cost. Opt Whale-Stone as your printer will be your wise decision, which can enjoy their industry-leading expertise and access to the latest technology for quality prints.

If you are opting for a supplier to provide nylon SLS 3D printing, it is vital to consider the following. Find a supplier that can produce quality prints and has a history of on-time, in-budget delivery. Our company is a custom nylon parts expert with a best-in-class reputation in the space, and has experience helping businesses of all types take their ideas through to realization. What’s more, finding the supplier that can stock most materials and finishes you need is also very important. We provides a range of nylons and finishes to suit whichever material you used, so your part looks good and feels great.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.