SLS material 3D printing is a game changer for manufacturing. Thanks to such progress, Whale-Stone has become the leader in offering SLS material 3D printing service with special materials of high quality demand for all kinds of fields. Whether you choose to use it case packer among a range of liquid filling machines Since its inception, Whale-Stone has always been dedicated to providing leading solutions with bringing success and efficiency.

Whale-Stone provides low cost wholesale services for SLS 3D printed materials, designed to help companies get high-quality manufacturing at a price they can afford. Whale-Stone utilizes economies of scale and efficient manufacturing to provide cost effective pricing. Whether you need prototypes, parts or finished goods, whale-stone wholesale pricing might help to reduce your cost without sacrificing quality! Buy Whale-Stone, get a better Nappy Bag With Whale-Stone nappy bag, you will enjoy the highest quality products and services at the most reasonable price.

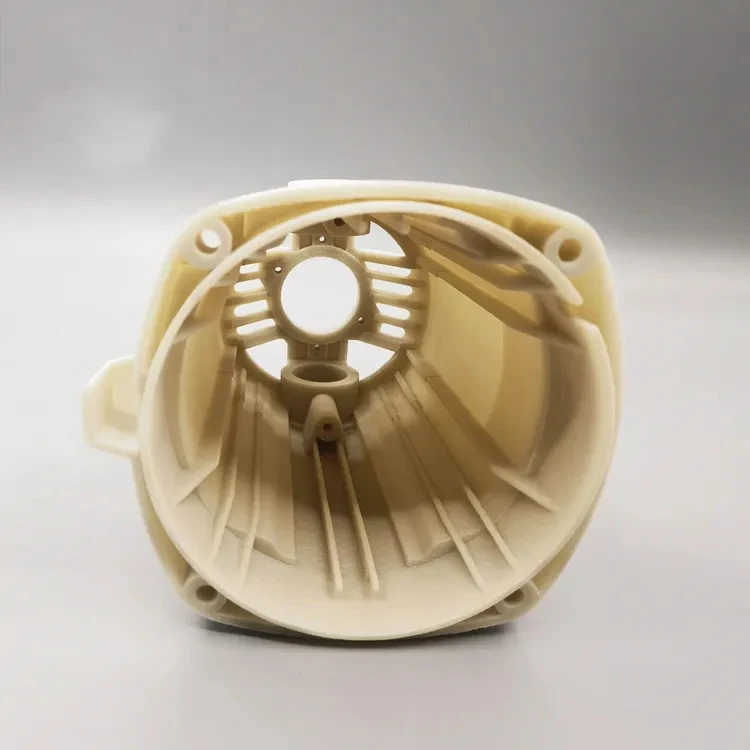

SLS material 3D printing can be applied to many industries, and we are right here to help you discover everything. Whether in aerospace or automotive, healthcare or consumer good, Sls 3d printing facilitates the fabrication of an array of products with high precision and speed. At Whale-Stone, we bring the experience of working with industries across the spectrum and meet your unique business needs. With needs for hundreds of custom parts, functional prototypes and end-use production-grade components Whale-Stone delivers creative solutions that meet demand in any industry. With Whale-Stone, anything is possible and your business can succeed in urbanization competition.

Before you can find a reliable SLS material 3D printing service, you'll want to take the time to do some research and choose which company is the right fit with this type of technology. Online is a good place to start your search, where you’re able to read reviews and narrow the list down between companies. You might also get referrals from your friends or co-workers if they have ever used Sls printing service before. You can also go to trade shows or industry events and speak with the representatives from various companies about what they have to offer. Finally, you want to pick a company with the experience that can deliver results and offer exactly what you are looking for.

There are however common problems that can occur throughouts this printing process on SLS material 3D printers. One such problem is warping, a condition in which the printed object contracts or distorts as it cools. This can lead to inaccuracies in the results and necessitate more post-processing to make corrections. Yet another problem can be bad surface finish which is created through not having the correct print settings or trying to print a part with low quality filament. Furthermore, Sls printing cost aren’t cheap either, particularly over a larger project. Make sure to consider your budget and timeline carefully before getting started.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.