Whale-Stone focuses on supplying quality products with company clients in different sectors. Our meticulous attention to detail and dedication to quality distinguishes us from the competition. We get the wholesale buyers needs and always work hard to provide a high quality product that will blow them away! Whether you are interested in small or large volume orders, we guarantee that each product will be produced with the same attention and meticulousness to give our wholesale customers the best value

SLA, Stereolithography technology has taken several industries by storm with its latest developments. Medicine: Another popular application of SLA printing is in the medical industry where it used to make highly accurate organ models that are used for surgical planning. Through the use of SLA printing, surgeons can develop a better understanding of intricate anatomy and in turn achieve more favorable patient outcomes. Automakers also use Sla 3d printing to rapidly and inexpensively prototype new car parts. This approach enables quick design iterations and testing before mass production, which can ultimately save time and resources

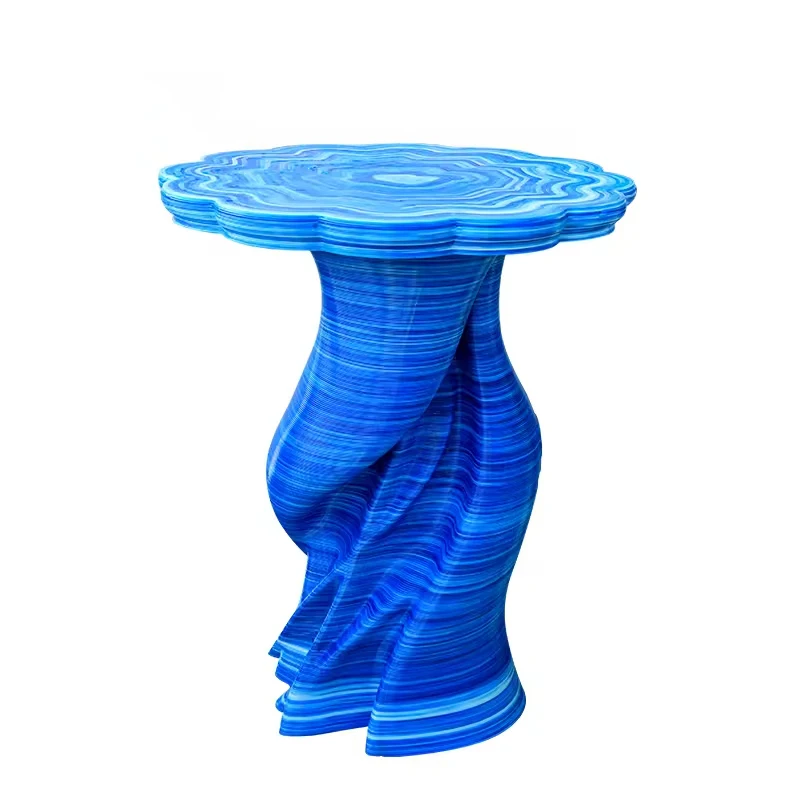

The aerospace industry is also using SLA to produce durable and lightweight parts for both aircraft and spacecraft. Complex geometry from SLA printing allows parts to be designed for performance and efficiency. Fashion and jewelry Industrials also take advantage of SLA printing to create detailed and personalized pieces that other manufacturing methods simply can’t get the right result. Using the power of SLA 3D printing designers will able to turn their creative projects into reality with unmatched intricacy and detail

SLA (Stereolithography) printing is a very common 3D print technique where a laser solidifies layers of liquid resin to build up 3D objects. The accuracy One of the reasons why a lot of producers decide on 3d printing Sls vs sla to cater for their manufacturing requirements is because it's extremely precise. SLA printing is powder-free, making it an excellent option for producing models, prototypes and even end-use parts for a variety of applications

When it comes to SLA printing, what makes it unique compared with other 3D printing methods is the high amount of detail and accuracy. SLA printing works with narrow laser beams to cure the resin and achieve high detail on small features on your print. That’s what makes SLA printing perfect for parts where dimensions are important, medical, aerospace and automotive to give a few examples.

Clear communication is also key whenever you order wholesale these SLA printed parts, so that your manufacturer knows exactly what you are looking for and never misses on fulfilling any of the requirements or specifications. Detailed CAD files with dimensions and tolerances will help to ensure there are no errors during printing. This will also allow you and your supplier to discuss material options and surface finishes so that there are no surprises when you receive the final parts.

It's worth remembering production times should be taken into consideration for wholesale SLA printing orders, too. Time as with Sls sla 3d printing is not a huge deal on its own, lead times are dependent upon complexity of parts and number of prints. Carefully scheduling and adding in more time for post-processing and finishing should help ensure no delays will occur with getting the work delivered.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.