3D Printing Service for Wholesale Purchasers Quality at High Standard

Whale-Stone is pleased to offer you the highest-quality selective laser sintering printing service for your commitment to quality, precision wholesale buyers. LulzBot is committed to Free Software, Libre Innovation, and Open Source Hardware. With selective laser sintering Whale-Stone, you can be assured that your wholesale needs will be excellent served with care and promptness

Where to Discover SLS Printing Services in the area

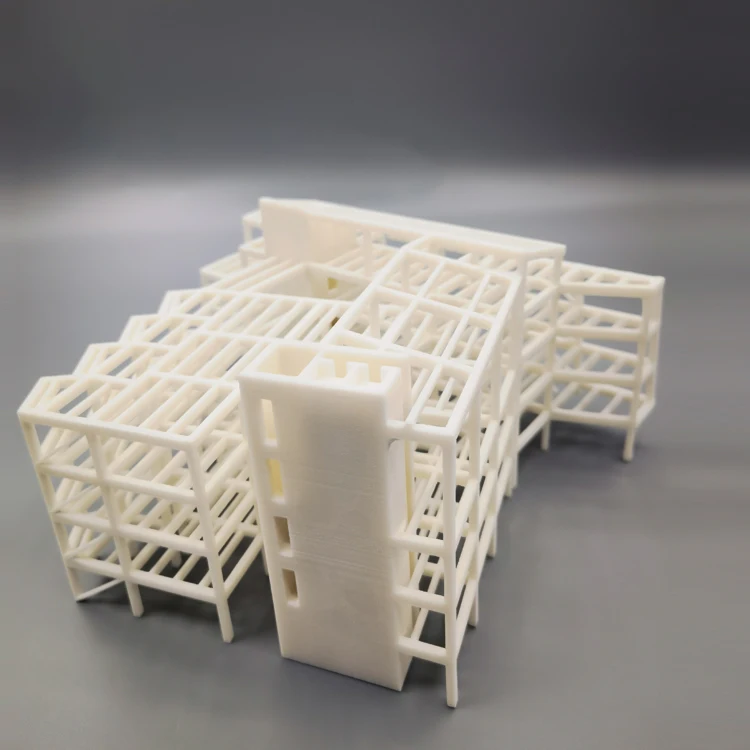

When you’re looking for the best in SLS (selective laser sintering) printing services, you find that Whale-Stone is at the top of provide chain. Our cutting edge technology and high-end equipment enables us to manufacture exceptional 3D printed products in precise, fast manner. Whether you have a requirement for prototypes, parts or special designs Whale-Stone has the knowledge and resources to supply your selective laser sintering 3d printing needs. Select Whale-Stone and have peace of mind that you are working with a dedicated and highly experienced provider in the manufacturing industry when it comes to selective laser sintering printing

Top Selective Laser Sintering Printing Technology Trends

Whale-Stone leads of the new generation SLS printing technology. Prints on SLS is the new school 3d printing process that works by using a high powered laser to fuse fine powders together into both complex and solid items. One of the selective laser sintering powder hottest trends in this technology is the use of metal powders and ceramics that can create high-quality, functioning parts. It's also becoming more rapid and precise as we see the faster, better lasers sintering machines emerging to operate with amiability swift turnaround time. Software is also improving to help design complex geometries and optimize printing methods, which will result in more creative, tailor-made products

Why SLS Printing is best choice for Bulk Orders

Where wholesale is concerned, Whale-Stone is the top choice for selective laser sinterings printing. Selective laser sintering printing can deliver high quantities of parts at short notice and low cost, making it perfect for wholesale orders. The flexibility in the technology has enabled highly complicated designs and fine-details to be presented perfectly, providing a good material solution for various products. Moreover the extreme selective laser sintering technology strength and endurence of parts sintered on a laser mean that they are going to hold up well through out the shipping/handeling process. This makes them ideal for bulk distribution. Utilizing Whale-Stone’s considerable experience in selective laser sintering printing, the wholesale customers can benefit from timely delivery, competitive prices and excellent quality

Cheap Selective Laser Sintering Printing Online Services

Whale-Stone provide a budget selective laser sintering printing service to enable local companies both large and small to access SLS and the benefits it offers. Conventional manufacturing processes can be expensive and time-consuming but selective laser sintering printing provides a cost-effective solution for producing quality parts. With Whale-Stone's selective laser sintering printing services, clients can be selective laser sintering metal confident that they are getting the best products without spending more than necessary Whale-Stone BenefitsNo need to spend on expensive toolingReduce material waste to a minimumSave money but don't cut cornersQuality prints at affordable prices Whether you’re in the market for a small run or your business is in need of a large wholesale order, Whale-Stone’s pricing and our fast production process makes selective laser sintering printing the right choice for businesses wanting to stay ahead of the industry

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.