An industrial production powerhouse Whale-Stone has done some of the most delicate 3D printing methods, including SLA, SLS, SLM. We pride ourselves on our innovation and high quality in the industry. We provide intelligent and environmentally friendly industrial manufacturing solutions, we have CNC R&D centers and new material manufacturing site.

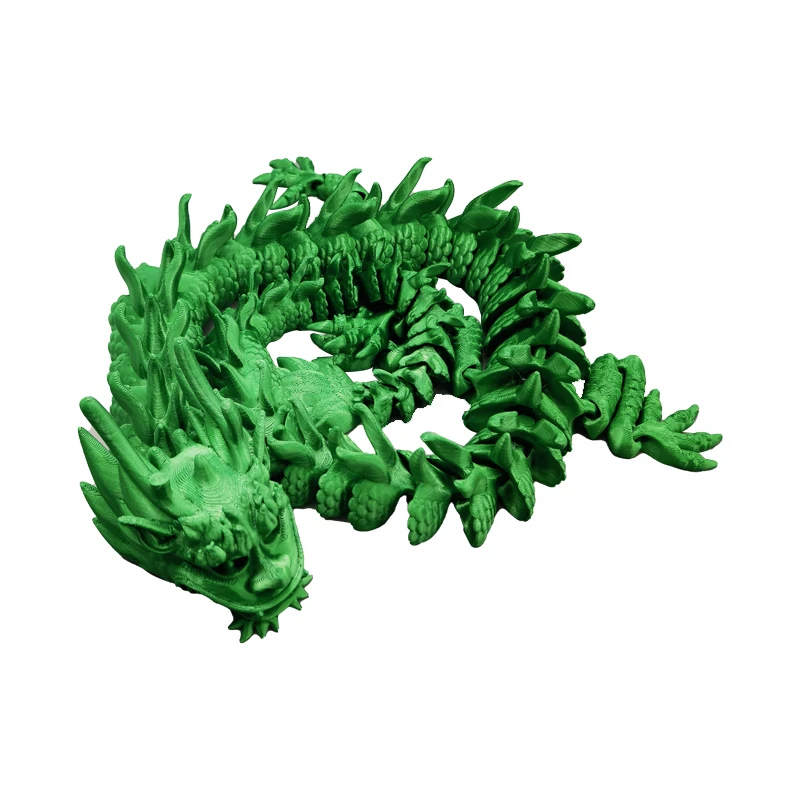

When painting 3D prints, proper finishing can be the difference between a quality model and a surface that shows print lines. Before you touch that paintbrush, give your 3D print a gentle sanding to remove any imperfections on the surface. Sand off any rough areas to give yourself a smooth painting surface with sandpaper. It is also useful to apply some primer to your 3D print, this will ensure that the paint can stick better and have a more even finish. If using a different type of paint, opt for a quality primer that is compatible.

To paint crisp and fine details on your 3D prints, try adding masking tape or stencils for a clean line and design. 4 Masking Doing this will ensure your lines are straight and colours separated nice and neatly, all over. And if you want to get automatic patterns or print your texture, ÜberStencils can be a way for it. Play around with different methods and gadgets and landing what suits your task most as well as satisfies desired effect.

For companies interested in improving the appearance of their wholesale 3D printed items, painting can make a big difference. If you introduce a mix of colour, finish and texture to your product, the results are visually striking and your range will be unique. Try metalline stains instead for a streamline look, or glossy finishes to fancy up your designs. Play with different painting styles to see what works best for your audience and makes your products look great.

Painting a 3D printed model can be a great way to bring the design to life. Acrylic paints are one of the top choices for completing a 3D print, the flexibility in terms of colors, fast dry time and vibrancy make it a winner. They also stick to nearly anything and are suitable for all materials you can use in 3D printing. For more long-wearing results, you can use enamel paints, that leave a shine and durable coating. Try out different types and brands of paint to determine which works best for your particular task and desired effect.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

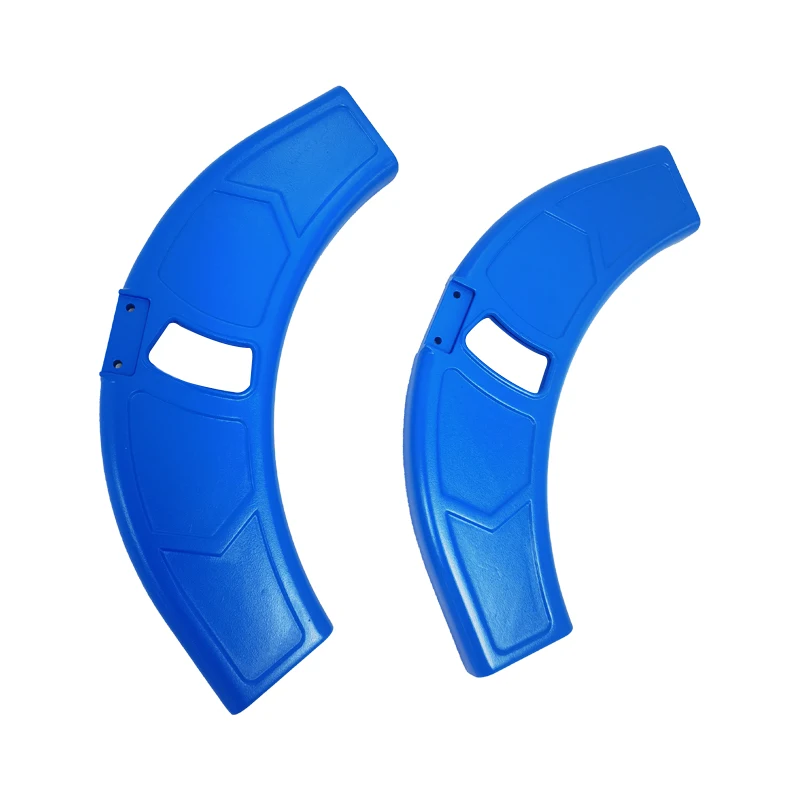

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.