3D printing is a really neat way to create points by producing them layer by layer. But to actually make points with it, you usually need a check of an object. You can use scanning to bring a product into an electronic form (so after that you are able to publish it out). This is a procedure that is ending up being progressively critical in wholesale manufacturing, where companies must produce lots of units of something efficiently and cost effectively. Whale-Stone is a scanning technology company that aims to help businesses build products fast and good.

Going forward, the future will be abundant with scanning for 3d printing in wholesale manufacturing. Just think than soon enough you can scan a thing or part that you need, literally at your palm’s reach! Companies can make points that are highly elaborate and detailed. That's, they have the ability to produce more idiosyncratic items that cater to people's rate of passions better. For instance, if a business needs an unique device that the stores do not carry, they can scan an current device, make changes to it and publish it. This conserves money and time. Plus, scanning can help cut down on waste. When you know exactly what must come from the printer, there is much less remaining. This readies for the environment, also!

3D scanning is crucial for replicating products. It is used to produce an electronic replication of an item. When it comes to 3D scanning at Whale-Stone, we can pick up every tiny information of the item you want us to remake. What this is to say: When we create a brand-new item, it will look exactly like the old one. If you have actually ever attempted to sketch something from memory, you know how hard it can be to remember everything properly. But 3D scanning gets rid of the thinking. The scanner after that takes photos from several angles and items with each other a complete 3D model. This model is highly photorealistic, and displays all the contours, shades and structures of the initial item.

Having actually an accurate electronic model is Paramount For several factors. For one, it gives developers and designers understanding into how the product was produced. They view what products were used, and how the item is put together. This gives us the capability to replicate the item precisely without mistakes. Second, 3D scanning conserves time. Instead compared to taking something apart and measuring it manually, we check the item and recover the information quickly. The outcome is, we can turn about a brand-new item much faster, which our customers love. Their orders don't take lengthy to find. Finally, 3D scanning may be cost-effective. As we make less mistakes, we waste less material and money. This allows us to maintain our prices reduced, and that is better for everyone.

There are methods utilizing 3D scanning that would simplify the fabrication process. Here at Whale-Stone we strive to take advantage of the newest scanning tools to make us work better and more rapidly. First, we begin with the original product. And we have a nice, clean clear resin 3d printing model that we can take into our designs. Once we receive the model, it can be edited using computer programs. If we want to make changes, such as increase the size or add new features, we can do so right on the computer. It is a lot faster than from scratch every time.

Then uv resin 3d printing is a tool that can just make us more streamlined in our workflow. With a digital model, we can easily share with everyone on our team. This allows everybody to view the exact same information and for developers, designers and manufacturing employees to get on the exact same web page. They can discuss ideas and decide with each other. Because we can all collaborate by doing this, there's no miscommunication and everybody is one the exact same web page. Not just that, we can also describe the checked model to do some prototyping. A model is the initial existent version of an item. We can try the model, to see if it works well, before manufacturing a bunch of them." By doing this we conserve time and avoid mistakes later on.

For wholesale buyers using 3D scanning, there are some missteps that can occur. You need to know these mistakes to prevent you from production them. We want to assist our customers in accomplishing the best results they can. Among one of the most regular missteps is not choosing the correct kind of scanner for the job. 3D scanners come in lots of forms, and each kind is suited to various jobs. You might want to use a various scanner to check a small object compared to to check an plane. Using the inaccurate scanner can outcome in reduced resolution checks which often neglect information you want consisted of.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

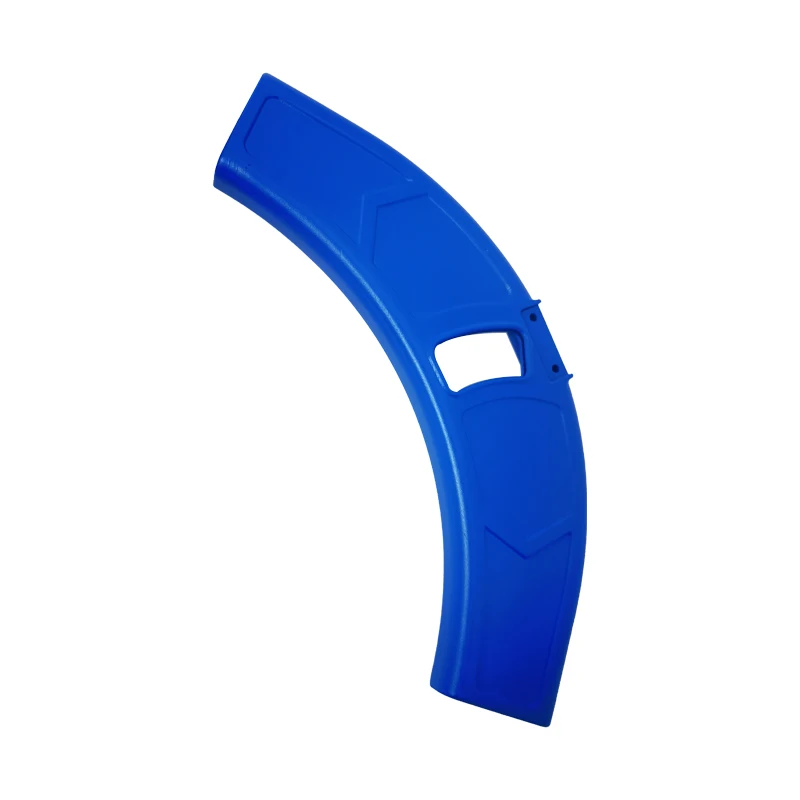

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.