This innovation has made incredibly complex designs, previously unimaginable; a possibility, thanks to Whale-Stone's world leading 3D capture and printing technology. From quick-and-dirty prototypes to design modification, the uses for 3D scanning and printing are countless. For instance, in the medical sector, 3D printing has partnered with personalized medicine to produce custom prosthetics or implants that meet every single patient's specifications. Not only does this level of personalization provide better patient outcomes, but it also makes production cheaper than the older ways.

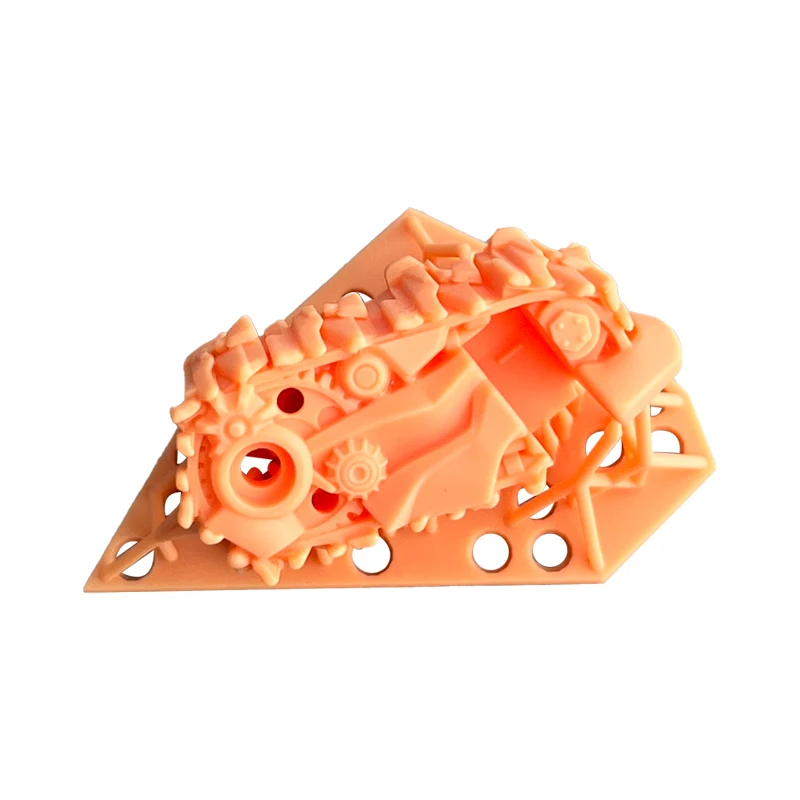

Additionally, 3D scanning is used in aerospace to produce lightweight but robust parts to be taken on board aircraft and spacecraft. These parts can feature complex internal structures which maximize strength and minimize mass, resulting in more cost effective, weight efficient designs that contribute to greater fuel consumption and operation. The automotive industry also takes advantage of 3d printing service with the ability to rapidly prototype new vehicle designs, and print spare parts on-demand while reducing lead time and inventory space.

And artists and designers have completely new creative scope with 3D scanning and printing, creating works that would never be possible before. Sculptures, jewelry and fashion accessories can be customized in detail and manufactured very accurately resulting unique and innovative designs. The motion picture industry uses 3D scanning to create special effects for blockbuster movies and video games, creating realistic characters and imaginary worlds that draw people into the imagination for entertainment purposes.

Furthermore, the choice of material is very important in 3D printing for achieving suitable mechanical properties and surface roughness. Also, compatibility between the 3D printer and the selected materials must be taken into account to avoid problems such as warping, lamination, or bad adhesion. Further, post-processing methods (e. g., sanding, painting or polishing) can be necessary to improve the appearance and quality of 3D-printed parts, which will increase fabrication time and labor.

Adding on, fine control is necessary in 3D scanning and printing to generate results that are at or above industry standard. Here are some of the important considerations to be taken for assuring quality manufacturing: Regular 3D scanner and 3D printer maintenance, calibration checks, direct waste disposal in a proper manner, use of updated software. Software incompatibility problems or firmware updates should also be tackled as soon as possible to prevent workflow halts and production downtime.

Whale-Stone epitomizes the new, emerging trends in 3D stamping and scanning designed for wholesale buyers. Due to technological developments, there are now 3d resin printing service within reach of relatively small businesses needing to simplify their production flows. A trend that wholesale buyers are leveraging is the 3D scanning of products to build precise and detailed digital models. This make for a fast and easy prototype or part cut, saving time and money over conventional manufacturing processes.

Another trend in 3D scanning and printing - people demanding products to be custom. Whale-Stone provides wholesalers with a cost-efficient way to customize and make one-of-a-kind products. With industrial 3d printing service, it is possible for business to capture the dimensions and spec of products in order to tailor them towards meeting the requirement of each customer. This level of customization is a game-changer for wholesale buyers who are looking to stand out in the market and find new customers.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.