Whale-Stone is excited to provide top-tier wholesale SLS 3D printers that can change the way companies look at manufacturing. SLS 3D printers use a laser to solidify powder material, allowing for durable and fantastically accurate objects to be made one layer at a time. The new printers can also create complex structures with intricate features, so they offer a useful tool for a range of commercial and academic applications. Whale-Stone's wholesale SLS 3D printer will make your business’ today, and leave the competitors tomorrow.

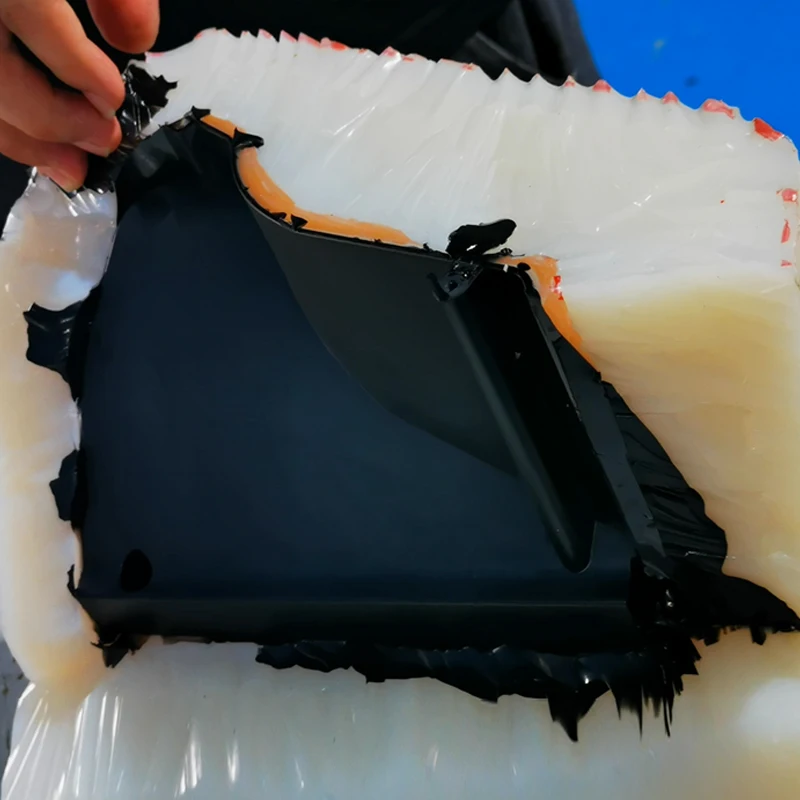

SLS 3D printers are often the favourite choice amongst wholesale buyers looking for manufacturing solutions due to the excellent type of products they can come up with. SLS is short for Selective Laser Sintering, which is a 3D printing technique during which the material powder gets sintered by a laser in an extremely local way to produce the final 3D shape. Thanks to this process, you can generate even the most detailed design and parts which is perfect for products with complex models.

SLS 3D printers are also known for being versatile, and capable of handling a variety of materials such as plastic, metal, and ceramics. This versatility allows you to prepare a whole range of goods to cater for your customers'wholesale requirements. Additionally, SLS 3D printing saves production costs as expensive molds or tooling are not needed as in traditional manufacturing processes.

SLS 3D printing and the future of manufacturing With technology getting better at an alarming rate, SLS 3D printing is shaping up to have a big part in the future of industrialization. This cutting edge technology has many advantages including faster manufacturing, less waste and having the possibility to have tailor made products on demand. SLS 3D printers allow manufacturers to prototype new designs, test different materials, and iterate on products to align with market needs.

Additionally, SLS 3D printing is quite ecofriendly as it generates nearly no waste in comparison to common production techniques. SLS 3D printers only use what is required to build a part, which makes manufacturing of products have a smaller carbon footprint. And with environmental sustainability taking centre-stage for both consumers and businesses, it’s no surprise that SLS 3D printing is an attractive option moving forward for the future of manufacturing.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.