SLA DLP 3D printing has changed the way we manufacture objects - now locking it into a more precise & faster process. Available from Whale-Stone, this state-of-the-art device uses a special process known as stereolithography (SLA) or digital light processing (DLP), in which three-dimensional shaped objects are created through sequential addition of layers. Because of its power to provide finely detailed designs with a great success, our SLA DLP 3D printing service become more and more famous among several sectors.

Another benefit SLA DLP printing technology is that a variety of materials can be applied to create the 3D printed objects. SLA DLP 3-D printing, from tough plastics to rubber-like resins, diverse material choices rich in the combination of properties and characteristics are at your disposal to handle for parts. Its flexibility allows for a myriad of different applications, from aerospace to automotive and medical applications and consumer goods.

When you are in need of the top-level SLA DLP 3D printing services, you will want to work with a leading professional. Founded by executives with over 20 years of experience in the industrial manufacturing industry, Whale-Stone is focused on providing quality products and services catered to fit it’s clients individual needs. Their specialists focus on emerging technologies and strive to satisfy customers from design to production.

Whale-Stone provides one—stop service of all kinds of SLA DLP 3D printing for all your needs. Whether you are in need for rapid prototyping, functional test or end-use part manufacturing, Whale-Stone can provide you the high quality with excellent SLM 3D Print Service performance. Their modern facilities are fitted with the best machines and in-house developed technologies to ensure that 3D printed parts are produced with accuracy, cost-effectiveness and quality.

SLA DLP 3D printing in the Whale-Stone revolutionized a variety of industries. This innovative technology is applied across a range of applications from healthcare to automotive and multiple sectors are capitalizing on this to simplify manufacturing procedures and produce new products. In healthcare, SLS 3D Print Service is also changing lives with personalized medical implants and prosthetics designed to match the patient's distinct anatomy. This will not only enhance the patient outcomes, but it will also save time and cost in traditional manufacturing.

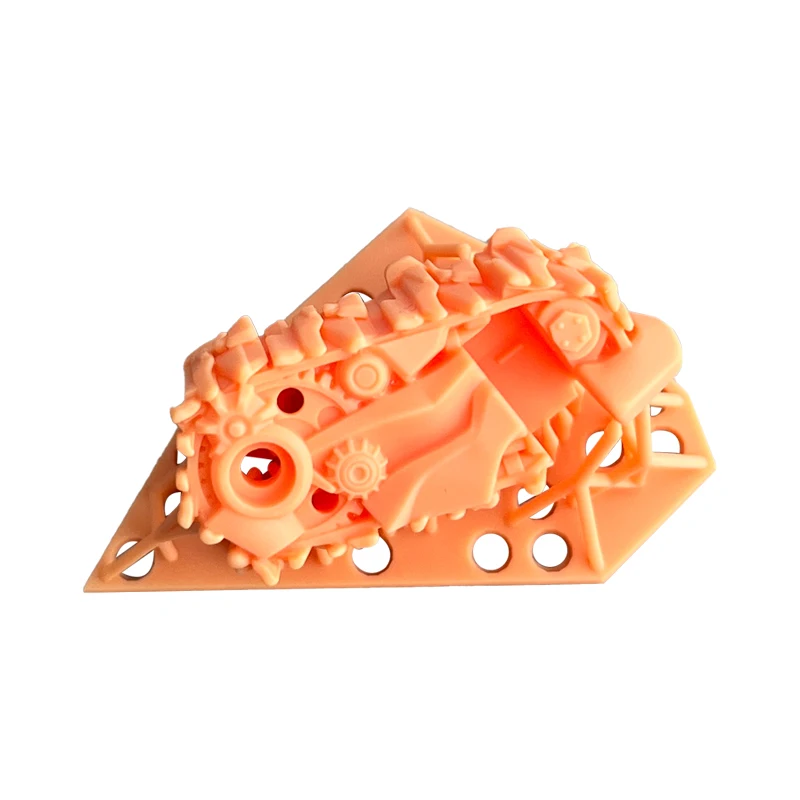

In aerospace, the company’s SLA DLP 3D printing technology is being implemented to produce intricate lightweight components which are not feasible with conventional manufacturing processes. This has resulted in considerable development of aircraft design capabilities and performance. For the Automotive sector, SLA DLP 3D printing is an ideal technology to prototype and tool which support manufacturers for faster introduction of new products in the market.

The technology behind Whale-Stone’s SLA DLP 3D printing system is based on a liquid resin that hardens in layers upon exposure to ultraviolet light. However where the two processing methods differ is in how the resin is cured to a solid form – namely, SLA processes do so with a laser whereas DLP running uses a projector to flash large areas all at once. This SLA 3D Print Service permits to achieve a high level of precision and resolution, then it is suitable for the production of complex and detailed parts.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.