At Whale-Stone, we have state of the art tech such as multi jet fusion 3D printing and ensure your products are made with accuracy and quickly. This creative process provides a cost-effective tool and superior quality in making 3D components with complex detail levels, smooth surface finish as well as size stability for both low end fast production applications. Read on to discover how multi jet fusion 3d printing service is transforming manufacturing as we know it and our customers.

Customizable design for wholesale buyer Whale-Stone 3D printed jewelry line has been using multi jet fusion. It means our customers can order a bespoke, blank shape and size. Eg a Fashion house can order mannequins to size, and where clothing style is (finally) chosen. It’s this flexibility that separates us from traditional production techniques and enables wholesale buyers to receive custom solutions tailored to their particular needs. With multi jet fusion sla 3d printing we can provide high levels of personalization and quality to our customers.

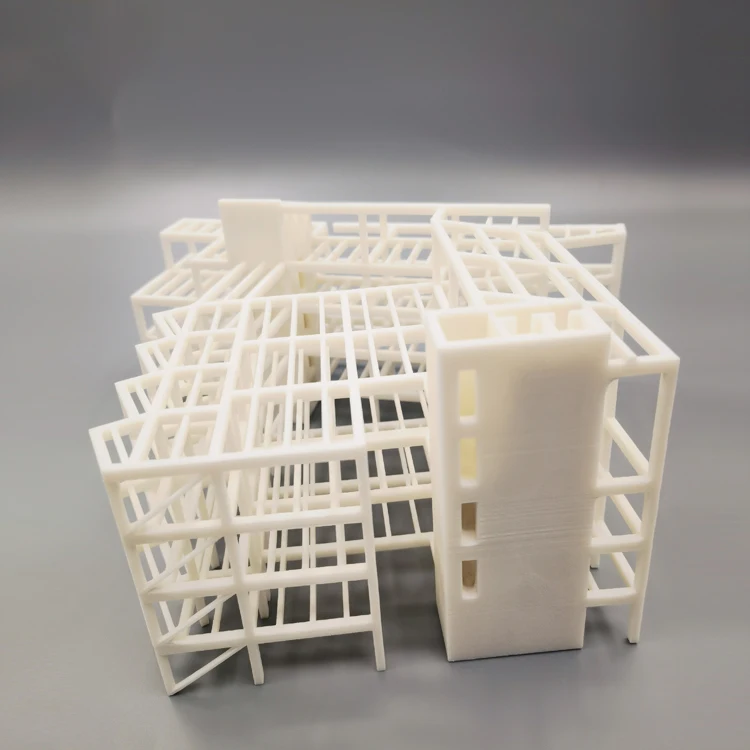

Whale-Stone leads the industry of "3D Printing" with the arrival of Multi Jet Fusion tech. This state-of-the-art 3D printing technology has changed the game in product development with its quicker production speeds and superior product quality. Multi jet fusion technology operates by depositing a binding agent and detailing agent on a powder bed with multiple print heads at the same time. This Stereolithography 3d printing can ensure a fine pattern of the design work, and leads to final product both durable and attractive.

There are a handful of advantages to wholesale production with multi jet fusion technology. One of the key benefits is its speed to produce products. By using multi jet fusion resin 3d printing service, it is possible to create complex designs in a fraction of the time that would be required by traditional manufacturing. So what that means can quickly make a lot of product to meet customer demand. Futhermore, due to additive manufacturing capabilities and the industrial MJF technology family each product is customized at scale, ready for use: every single item can be fit to customer specifications without any quality loss.

While there are many advantages of multi jet fusion technology, it is not without its limitations. One possible disadvantage is the cost of machinery and materials. A multi jet fusion 3d printing prototype can be tens of thousands of dollars, which is pretty expensive considering a create your own type business or the fact that you are a startup. Also, product size may be restricted when they are produced with this technique. They also need to have in mind the size and potential cost of their products, and if multi jet fusion is worth considering for production. Although there are limitations, the benefits of multi jet fusion technology outweigh any negatives, and for wholesale production it is an ideal technology.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.