Searching for an FDM printer for your business? Whale-Stone has got you covered! Whether you're a small start up or large corporation, the right FDM printer can make all the difference in your production process. Here is how Whale-Stone can assist you with wholesale FDM printers and where to get the best deals

Whale-Stone is a well known brand in the manufacturing industry that has got you covered with multi-options for FDM printers, designed to suit every business at any level. Whether you're on a budget, in need of something portable or want a powerful heavy-duty industrial grinder, we have the product for your needs. Our Fdm printing are prided for their quality prints, dependability and convenience. At Tacklife, we aim to manufacture the best products that inspire our consumers to live a more convenient, secure lifestyle -We have our professional products monitoring team to focus on every single detail that matters to you and develop well-made, portable, exquisite products.

If you are looking for the most potential in FDM printers, Whale-Stone has got your back. Plus we can provide you with factory-direct prices and special offers that will allow businesses to afford superior printers without emptying your account. Whether you need to supplement or replace your antiquated equipment, Expand your production rate. We have the answer. Get insights from our team Let's build your brand together, Enter You will get Insider deals, discounts and promotions We work with Whale-Stone and you can buy at a better rates then Public! Never miss out our hot deal and take your business to the next level with Whale-Stone's FDM printers

Like any other 3D printer, while working with a Whale-Stone FDM printer, you may run into some common problems which impact on the quality of your prints. One common problem is warping, where the edges of your print warp upward as they are being printed. The best way to avoid this is to keep your Fdm printed sculpture in a location that allows it to balance out its temperature. You can also print with a heated bed or add some adhesive to the build plate so the print adheres better.

Very close to this is stringing, which leaves thin whiskers of filament across your print. Lowering the retraction settings in your slicing software should help minimize the stringing. If you have retraction distances and speeds that are insufficient, increase these for better mitigating stringing and to achieve better print quality.

There are several simple steps you can take to ensure that your Fdm 3d printing with your Whale-Stone printer is good. First of all, keep your printer calibrated so that it prints accurately. Ensure that bed is level and nozzle height to avoid problems such as the nozzle jamming, under extrusion or over extrusion.

Feel free to contact our customer service, send us email or call us directly for fast help. From technical troubleshoot TING to questions on how you can improve your workflow with our product, we are always here for you.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

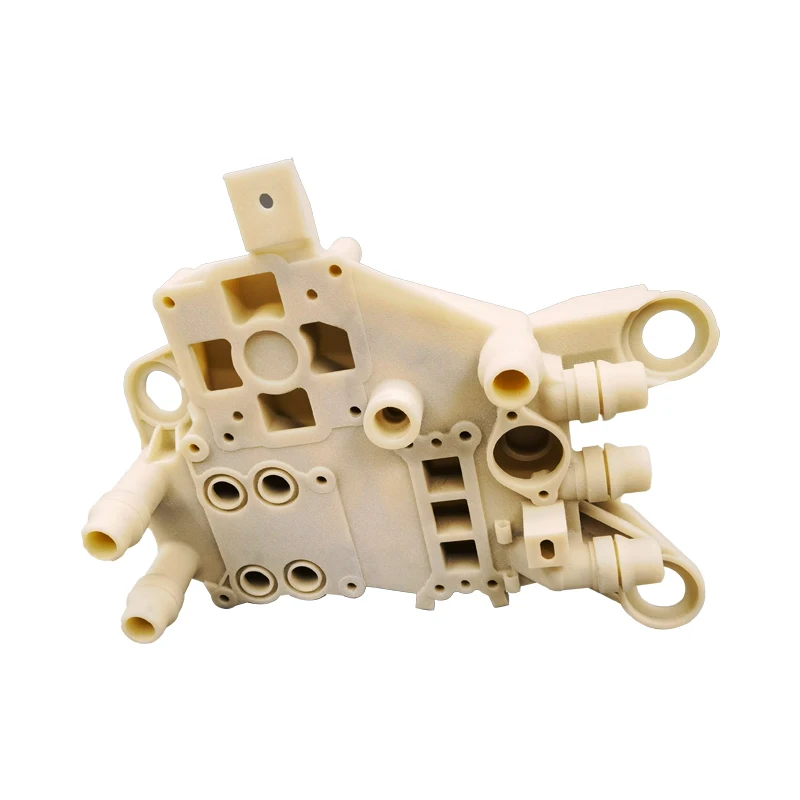

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.