When it comes to wholesale production, determining the #1 3D printing technology will depend on several factors. Different technologies on the market that can help with wholesale manufacturing SLA (Stereolithography) and DLP (Digital Light Processing) are two popular options that provide different benefits when it comes to wholesale manufacturing In this post, we will discuss the advantages of SLA and DLP technologies for higher-quality wholesale production, and help you decide which is better. Learn what Whale-Stone could do for your wholesale business from SLA and DLP printing.

3.1 Considerations for Wholesale Production There are a few key aspects to take into account when choosing a 3D printing technology for wholesale production, which include: speed, accuracy, material compatibility and cost effectiveness. SLA and DLP: Both of these printer types are best at producing extremely detailed, high-end parts, which lends themselves well to batch processing. Whereas SLA uses a laser to cure liquid resin layer-by-layer, DLP uses a digital light projector to flash whole layers at once. Each technology has its advantages and disadvantages, which is why it’s important to know more about the specific production needs of your wholesale business in order to make the right choice for you.

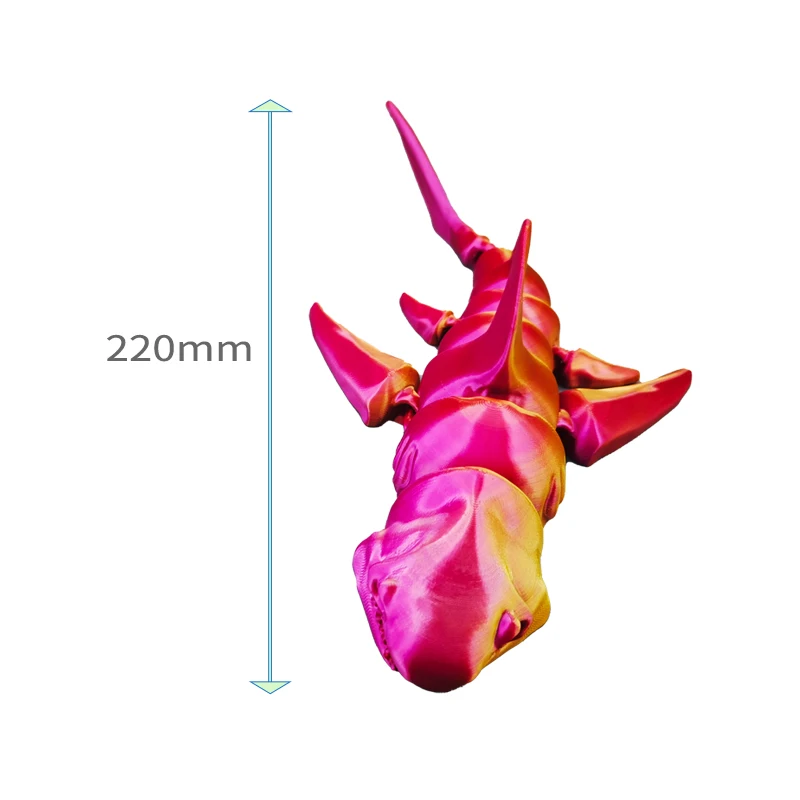

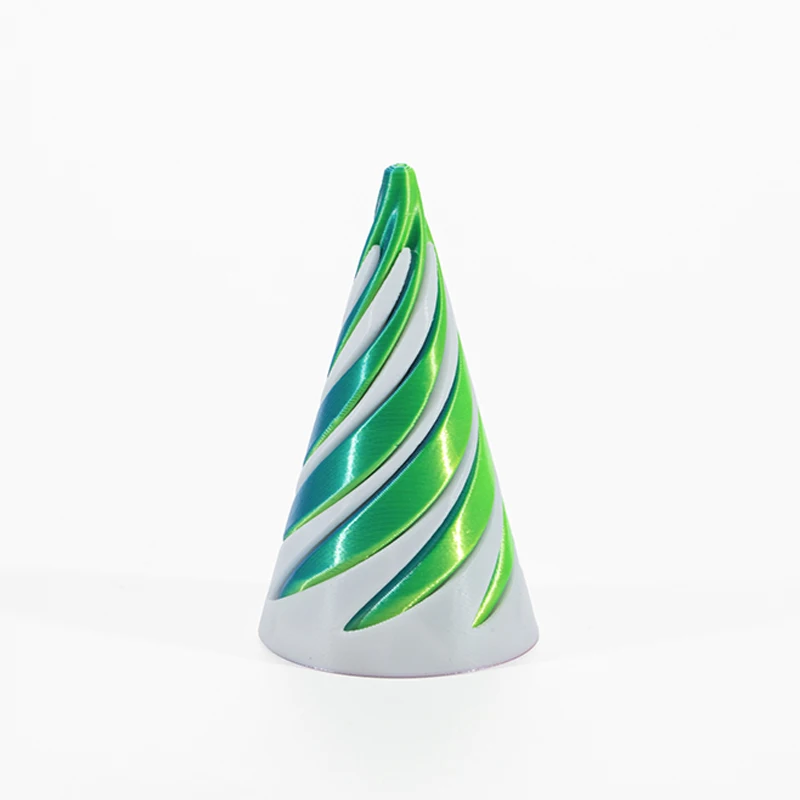

1.SLA and DLP technologies has a lot of advantages for wholesale process. SLA provide excellent accuracy and surface finish, which makes it the ideal process for building precise prototype and functional components with fine details, such as smooth surfaces of small parts DLP, meanwhile, features faster print speeds and can be cheaper for mass production. Engineering-material compatibility Both “edge-lighting” and “surface-emitting" technologies are offered in a broad range of materials, including engineering resins that will pass appropriate industry standards for strength and durability. With the use of SLA and DLP, Whale-Stone can help you get remarkable wholesale manufacturing without any further ado.

It all depends on the requirements and prioritization of your business model when it comes to wholesale production between SLA and DLP. Print results SLA printing provides highly detailed prints down to a microscopic layer thickness and high surface quality, making it the technology of choice for where fine detail is needed. On its part, DLP printing ends with faster production times and the possibility of cost-efficient solutions for high quantity demand. Whale-Stone can aid you in deciding which to use for you wholesale business needs and the products that you aim at having produced.

You can higher quality and more productive in your production workflow by adding SLA/DLP technology into the wholesale manufacturing. From complex prototypes, functional components, to specialized parts, Whale-Stone's experience with SLA and DLP printing can assist you in obtaining the best performance. Our mastery of additive design, commitment to innovation and proven performance guarantees that your wholesale offering will lead the market place. Discovered the accuracy, reproducibility and consistency of SLA and DLP with Whale-Stone for wholesale products.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.