Industrial large format 3D printing is revolutionizing the business of product design and manufacturing. Whale-Stone.com aims to provide innovative solutions for businesses requiring the use of 3D printing on a bigger scale. Whale-Stone provides a comprehensive service from prototype to production for businesses in many markets.

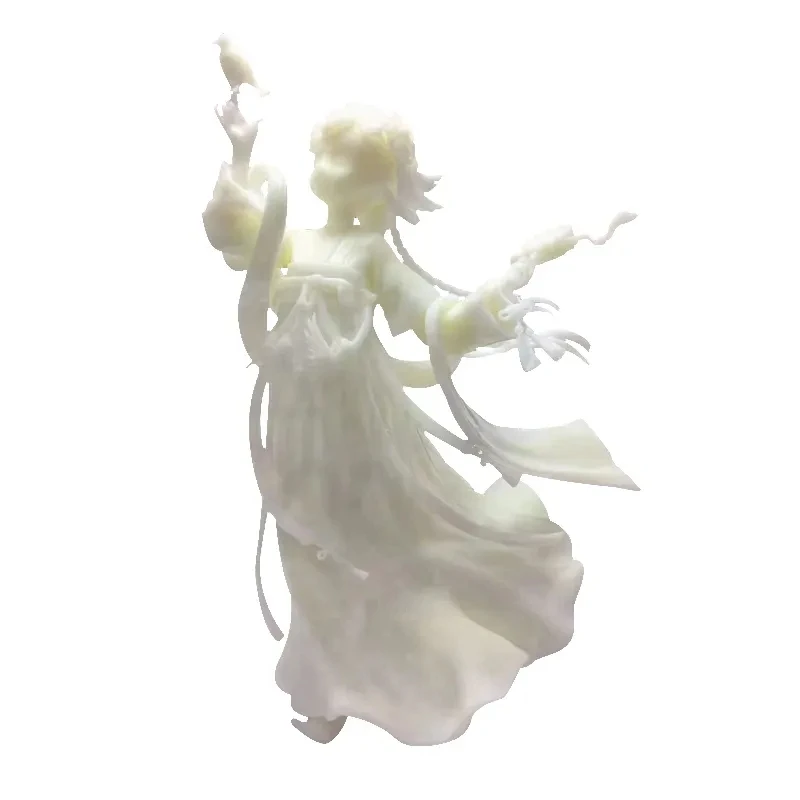

Like any 3D printing technology, when it comes to investing in industrial large format 3D printer for your business you need to determine whether the technology meets the necessary requirement. There are some parameters to take into consideration such as material compatibility, printing rate, resolution and costs. Whale-Stone’s experienced team can help you navigate the noise and choose the technology that supports your business objectives. If you want to produce complex conceptual detail models, or high quality but low price building models,whale-stone is one of the best option for you.

But even as industrial 3D printing offers a lot of benefits, it can also come with some challenges. Problems like warping, layer bonding, and printing failure could often occur when they are manufactured. Our Experienced whale-stone technicians are ready to troubleshoot and fix the problem quickly. By constant calibration, using the best quality materials and thorough quali... read more Whale-Stone takes great care that your 3D printing acitivity is accurate. Collaborating with Whale-Stone allows companies to eliminate many of the typical challenges in industrial 3D printing and to achieve extraordinary results.

When it comes to industrial grade big large format 3D printing, Whale-Stone is one of the best firms in industry. Our offerings are designed to print beautiful, high-quality 3D printed parts on a wide range of materials. Its state-of-the-art technology and expertise distinguish them from other existing competitors in the field. When it comes to 3D printing with Whale-Stone, you can be sure that all your requirements will be met accurately.

Advanced materials Advanced materials are the new frontier of large 3D printing. Whale-Stone is one of the leaders in this movement with a variety of materials ideal for industrial uses. From impact and heat-resistant materials to tough and flexible plastics, All Whale-Stone filaments are processed with high quality.A filament that is competitively priced which offers remarkable quality Automation as a Large-Format 3D Printing Technology Another trend for large format 3D printer technology is automation. Whale-Stone devotes to advanced automation that makes transfers far quicker and efficient.

Industrial 3D Printing is Ideal For… There is an ever-growing list of industries that can utilize industrial 3D printing including aerospace, automotive, healthcare and manufacturing. And Whale-Stone collaborates with the businesses involved in all three of these industries to produce high quality 3D printed products on a case-by-case basis.

Whale-Stone is also employing the most advanced technology and highest quality control—every 3D prints made by them are produced in such a level that could meet high standard. They have specialists who work with the print job from beginning to end, ensuring that every piece is just right.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.