Granite Devices, the developers of world-class servo drives and Servo Drive IO's are proud now to be able to offer all 3D Touch Probe post-processing by Whale-Stone. After you have finished your model we will help ensure that it is perfect! Our professional finishing provides the best possible finish and durability to your 3D printed parts. Through increased efficiency and quicker turnaround times, we allow you to outpace the competition and get ahead of industry needs with excellence.

We at Whale-Stone know that you value a continuous, efficient 3D printing process. Our professional software can help maximize the potential throughout every stage of your project and we offer a range of Lab Cutters that are perfect for getting the most from our range of Mould Making materials. Through the utilization of state-of-the-art technology and advances in methodology, we enable your production time to decrease while less waste for you to worry about -so you can focus on glorifying the customer with a great product.

In the manufacturing industry, quality comes first and with Whale-Stone we promise to take your 3D printed parts up a notch with our top of the line finishes. We use new technology and materials in our process to help us guarantee super quality specifications for each of our products. No matter if you need to refine the surface finish, improve the structural strength or reinforce functionality of your 3D printed parts, our advanced finishing services can help you take your work to a whole new level. Click here to learn more about our customized high-quality ABS rubber rapid prototyping vacuum casting service.

Using our post-processing know-how we can support you to take the quality and workmanship of your products to a higher level. With final processing tasks ranging from surface imperfection repair to fine detailing and texturing, our state-of-the-art finishing processes will turn your 3D printed parts into works of art. With Whale-Stone's commitment to quality and newness, you can lift the level of your end-products and establish new industry benchmarks in manufacturing.

From automated sanding, polishing and other surface treatment solutions to robotic painting and coating, our post-processing services are optimized to simplify each stage of the production process. We can provide you with modern tools that you need to ensure your production flow processes are as efficient and effective as possible. – With Whale-Stone's revolutionary post-processing options, you can speed up the manufacture of your products and increase yield and profit. Click here to find out more about our custom aluminium alloy 3D printing factory.

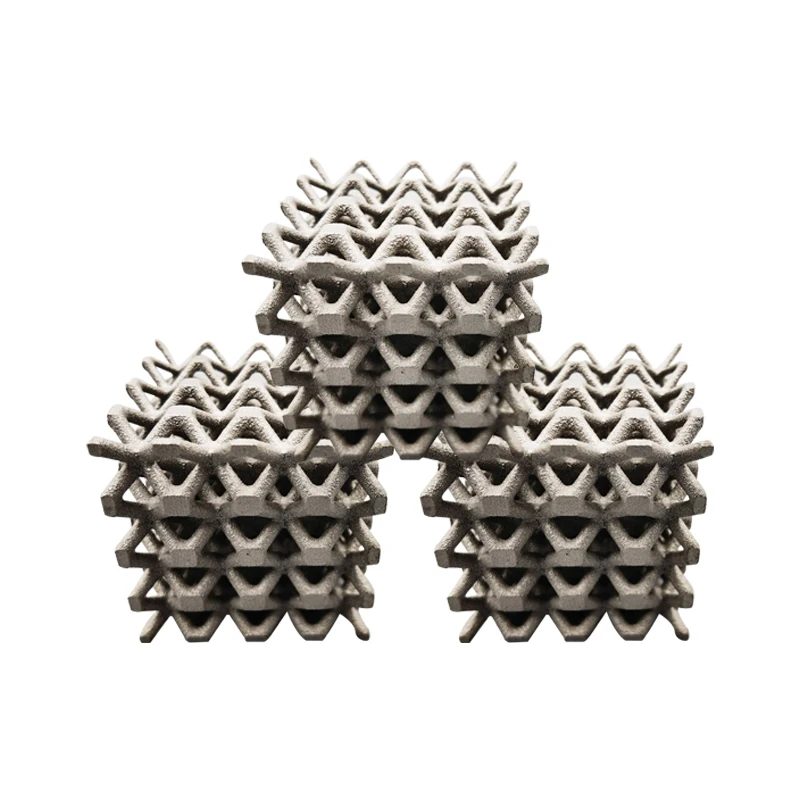

Product design and manufacturing processes are all about durability and aesthetics, at Whale-Stone we focus to add value in your 3D printed parts, by adding the finishing touch. Our experienced staff of artisans and technicians are ready to polish, paint or coat your products with the same attention to perfection that we apply to every project. If you want to improve the structural strength as well as visually enhance your parts, our fine finish can take your product where it needs to be. Learn more about our custom 3D printed stainless steel metal parts rapid prototyping and CNC service micro machining factory.

Thanks to the use of high tech and material when it comes to post-processing we are able to support you in producing products that will be not only durable and functional, but also catchy. Read more about our 3d metal printing! And with custom finishes and textures or even the general surface finishing, our master finishers can take your 3d printed parts from raw to a work of art. With our dedication to quality and focus on detail you can improve the longevity and appearance of your products and add value for your customers.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.