Whale-Stone is technologically leading in the industry of industrial manufacturing, such as laser melting for 3D printing. This revolutionary new approach enables the production of complex, precision components at high speed and with unparalleled accuracy. So let's discuss how the laser melting 3d printing service from Whale-Stone can revolutionize your business.

Whale-Stone has cost-effective bulk prices for large order of laser melting 3D printed parts. Economies of scale/ cost efficient production process, whale-stone can offer you the most competitive component by quantities. Whether you are looking for thousands of intricate parts for a new product line, or specific parts to complete an unusual project, Whale-Stone's commercial options have your covered.

There are so many advantages in which your business can benefit as the result of laser melting 3D printing. For a start, such advanced manufacturing provides the ability to rapidly prototype and manufacture new designs, which in turn can lessen time-to-market for new products. No matter if you are a small startup trying to move fast on designing products or you are from the corporate world heading towards launching a new product, this 3d printing technology will bring your player to be competitive.

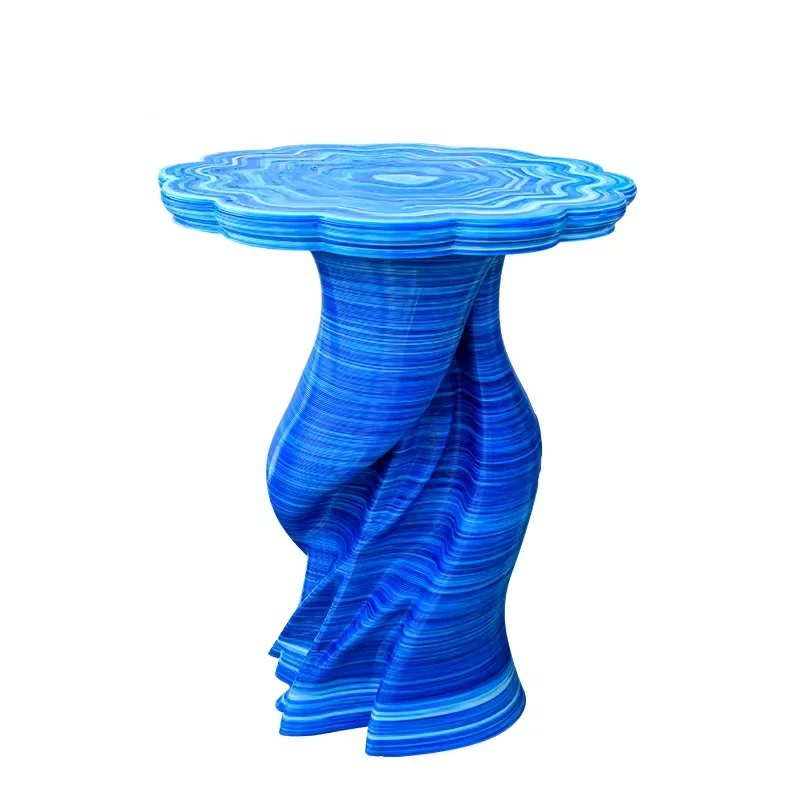

Moreover, laser melting 3D printing technique possesses unmatched design freedom to fabricate the complicated geometries and structures which would be unfeasible by traditional generation. This allows for various product designs and improve performance. With the ability of laser melting 3D printing technology, you can make your products in market distinctive, and appeal to customers with unique and high quality Integrated Parts.

Furthermore, laser melting 3D printing is known as an environment-friendly manufacturing method with low material waste and required energy. As a company that prides themselves in innovation and environmentally friendly manufacturing, adopting laser melting 3D printing to your production processes, can help establish your business as an “eco-manufacturer” leader. If you believe in the environment as we do at Whale-Stone commit yourself to show help reduce your carbon footprint for a healthier planet.

There are several things that can/potentially go wrong if you’re 3D printing with lasers. One thing that can go wrong is porosity, which are small holes or gaps left within the object you have designed as it gets printed. To address that, the powder bed needs to be heated up properly before any printing. This industrial 3d printing service aids in removing any entrapped air, which can cause porosity.

Another notable feature of laser melting 3D printing is the potential to enable high-strength functional parts. This stems from the fact that printer setups are typically adjusted on a layer-to-layer basis, allowing the exact characteristics of the final object to be controlled. Therefore, parts produced by laser melting 3D printing are commonly stronger and more reliable than their traditional counterparts.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.