OEM-tilpasset 3D-printing, tilpasset klar harpiks, rask prototype, SLA DLP, gjennomsiktige plastdeler

- Oversikt

- Relaterte produkter

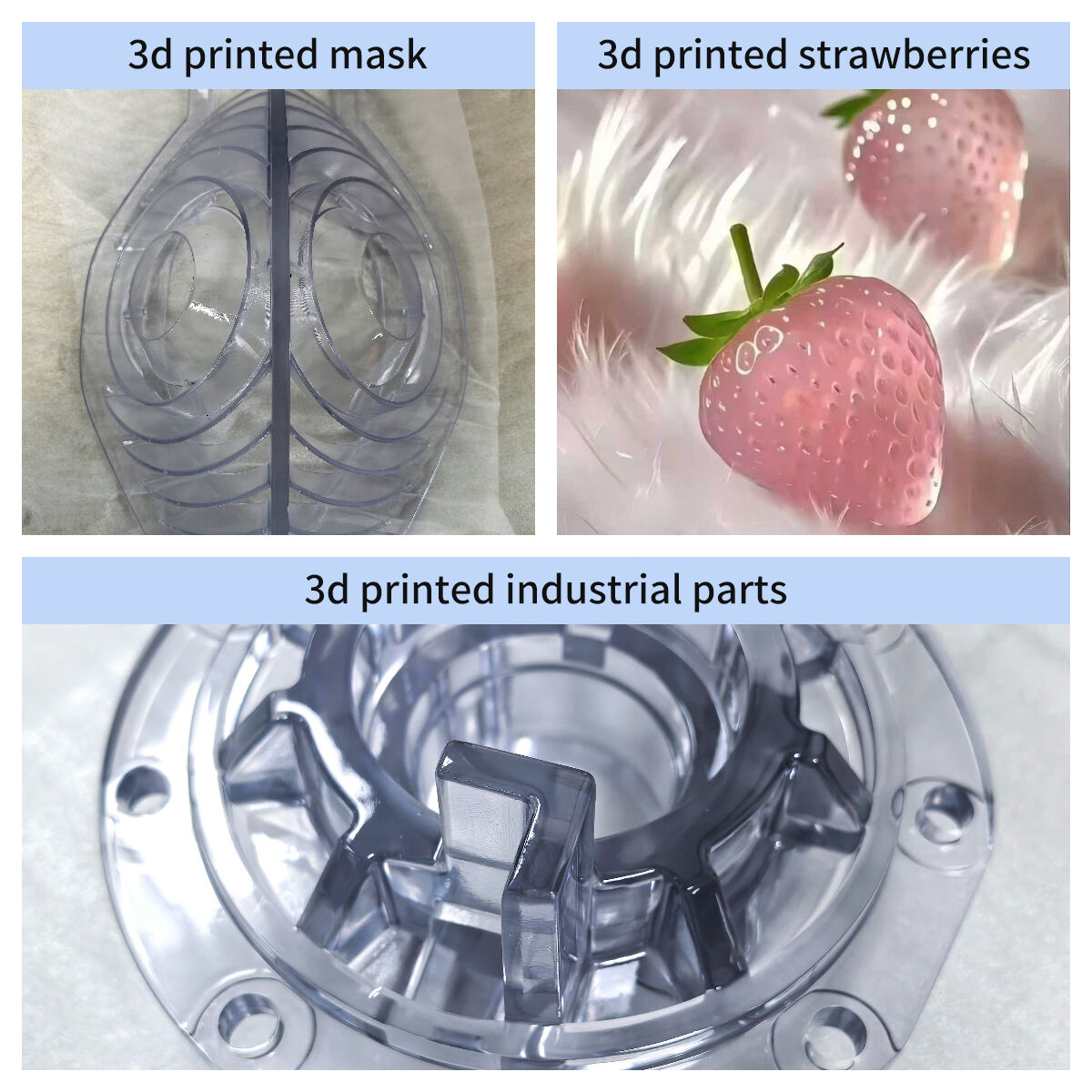

Produktutstilling

Spesifikasjoner

| punkt | verdi |

| Cnc maskinering eller ikke | Ikkje CNC-bearbeiding |

| Materialegenskaper | Resin |

| Type | SLA/DLP 3D-utskrift |

| Overflatebehandling | Kundens ønske |

| Tjeneste | Tilpasset OEM |

| Størrelse | Tilpasset Størrelse |

| Nøkkelord | 3D rapid prototyping |

| Tegneformat | STL. STP. STEP. osv |

| MOQ | 1Stykke |

Eksempelvisning

Selskapsprofil

Suzhou Whale-Stone 3D Technology Co., Ltd. er et heleid datterselskap av Shenzhen Kings 3D Technology Co., Ltd., et viktig investeringsprosjekt innført til Wuzhong-distriktet i Suzhou by, Jiangsu-provinsen. Selskapet dekker et areal på over 4 500 kvadratmeter og har en 3D-printingssenter, et senter for bilkonstruksjon og utvikling, et CNC-precisjonsbearbeidingssenter, et senter for forskning og utvikling av nye materialer, et senter for rask moldproduksjon, et senter for rask produktproduksjon, et senter for produkts anvendelsestjenester og syv andre kjerneavdelinger. Vi er dedikert til å tilby kunder SLA-printing, SLS nylon-printing, SLM-printing og tjenester for rask produksjon av små serier med sammensatte former.

Våre hovedtjenester

Selskapsfordel

Ofte stilte spørsmål

1. Tilbyr dere en taushetsavtale (NDA)?

Svar: Sjølvsagt ! Vi tar beskyttelsen av våre kunders immaterielle rettigheter og konfidensialitet av design svært alvorlig. Vi vil signere en NDA etter forespørsel for å sikre at din informasjon er fullstendig sikret.

2. Hvilke 3D-utskriftsteknologier tilbyr dere hovedsakelig?

Svar: Som profesjonell leverandør av 3D-utskriftstjenester har vi har over 400 utskrifter ere . Våre tjenesteytelser dekker omfattende ulike 3D-printprosesser, inkludert SLA (fotosensitiv harpiks), SLS (nilon pulver), SLM (metall), FDM (filament) og FGF (kornstoff), samt integrerer CNC-bearbeiding og vakuumstøping for å tilby en helhetlig produksjonsløsning.

3. Hvilke utskriftsmaterialer er tilgjengelige for valg?

Svar: Vi tilbyr et bredt utvalg av materialer, inkludert: Harpikser, PA12, PA11, Nylon + Glasfiber, Nylon + Karbonfiber, Aluminiumslegering, Rustfritt stål, Verktøystål, Krom-zirkonium-kopper, PLA, ABS, TPU, PETG, PEEK, PC, PP, PAT10, PAU20, etc.

4. Hvorfor er rask prototyping nødvendig? Kan de utskrevne gjenstandene brukes som ferdige produkter?

Svar: Rask prototyping lar designere verifisere produktet, forkorte utviklingssyklusen og sikre at nye produkter raskt kan møte marknadsbehov.

Med teknologiske fremskritt har 3D-print utviklet seg fra «rask prototyping» til «direkte produksjon». I industrier som luft- og romfart, bilindustri og medisinsk teknologi, brukes 3D-printede komponenter allerede direkte som endelige ferdigprodukter.

5. Hvilke filformater må jeg levere?

Svar: Vi aksepterer vanlige 3D-modellfilformater som STL, STEP, OBJ osv., som er bransjestandarder.

6. Kan dere hjelpe med å reparere problematiske modellfiler?

Svar: Ja. Vi tilbyr gratis grunnleggende modellinspeksjon og reparasjon av mindre feil. For mer komplekse modellproblemer kan det påløpe en liten gebyr, eller vi kan gi anbefalinger for reparasjon.

7. Hvilke etterbehandlingsvalg er tilgjengelig etter printing?

Svar: Vi tilbyr ulike typer etterbehandlingstjenester for å forbedre produktets utseende og ytelse:

Grunnbehandling: Fjerning av støttestrukturer, sliping.

Andre behandlinger: Sandblåsting, farging, dampglattlegging, grunning, maling, elektroplatering, polering, tapping, innsetting av innvendige gjenger (f.eks. muttere), etc.

8. Finnes det en minimumsordrekvantitet (MOQ)? Tilbyr dere gratis prøver for store ordrer?

Svar: Vi forstår at kundens behov varierer, så det er ingen minimumsordre – selv én enkelt del kan bestilles. For store ordrer tilbyr vi gratis testprøver, men fraktkostnadene dekkes ikke.

9. Tilbyr dere global shipping-tjenester?

Svar: Ja, vi samarbeider med større internasjonale logistikkbedrifter for å tilby trygge og raske frakttjenester til kunder over hele verden. Fraktkostnadene beregnes separat basert på destinasjon og vekt/volum av pakken.