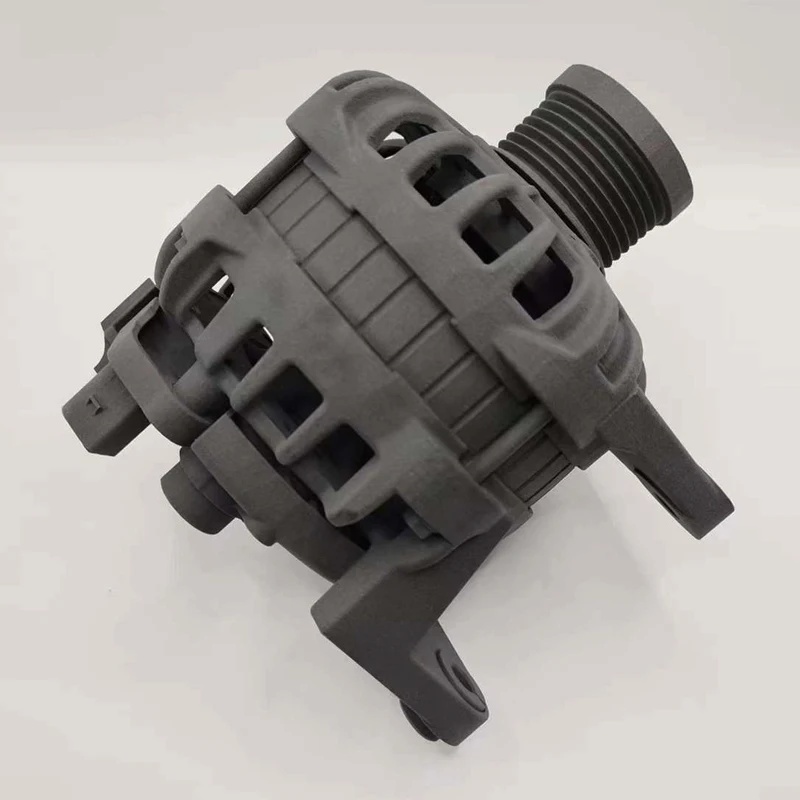

The SLS nylon printing is revolutionizing how things are made, significantly the parts you actually use on a daily basis and not just for prototyping new ideas. Here at Whale-Stone, we see this technology enabling factories to produce real products, that are durable and do their jobs well. Instead of just printing a lot of test versions, SLS nylon gives companies the ability to manufacture strong, flexible parts that matches exactly what their customers need. The nylon the parts are made of is strong but light, so the pieces can withstand wear and tear without becoming heavy or breaking quickly. That’s a big deal, because it means there are practical ways to make things faster and with much less waste. When you think about making things, it’s not just stringing stuff together, SLS nylon printing is another method for forming parts one layer at a time, achieving complex shapes that were difficult to achieve with traditional tools. Whale-Stone employs this technique to assist companies in procuring parts that are ready for use immediately, which saves time and funds while keeping quality high. SLS nylon printing is about more than just samples, it’s about creating parts that work every day in the real world.

Reasons Why We Love SLS Nylon For Custom Wholesale Printing

SLS printing with nylon is an ideal option when cost and volume combination in large-scale, custom wholesale production maximizes speed, durability, and flexibility in ways other methods cannot. At Whale-Stone, we deal a lot with customers who need to parts printed fast, but they also want the strength needs for that part to hold up. The material used in SLS nylon printing, is more durable and can bend without breaking, so the parts have a longer life span. Part of the appeal is how seamless it can be to switch designs, without halting production. Small tweaks like changing a circumference, for example if a customer wanted a slightly different shape or size we could adjust the digital file and print that new version right there. That is much faster and less expensive than in traditional manufacturing, where new molds or tools might be required. And since SLS printing builds parts up layer by layer, it’s possible to make complex geometries, some of which would be unfeasible or highly cost-prohibitive with other methods. It’s perfect for custom orders where each piece might be slightly different. Customers will occasionally request parts with tiny holes or special textures, and SLS nylon printing does a great job accommodating those details. And, of course, printing a bunch of the same part at one time in a single batch saves money. We at Whale-Stone are aware of the needs that businesses have for quality products but also quickly and affordably, representatives with Whale-Stone wrote. This is precisely why our SLS nylon printing process is such a great fit for custom wholesale production we’re able to quickly fulfill those unique needs without long lead times or crazy high costs.

How SLS Nylon Technology is Making Manufacturing End-Use Parts More Efficient

Efficiency is crucial when it comes to creating end use parts and SLS nylon technology goes a long way in achieving that. And at Whale-Stone, we have witnessed how much time this technology saves in going from idea to finished part. The traditional way of manufacturing often takes several steps, creating a mould, testing out samples, fixing problems and then making the part. We can bypass many of these facilities and skills because SLS nylon printing involves taking a design directly from the computer and creating a finished part. This translates into less errors and time spent correcting the same. Another thing is that SLS nylon parts often require less post-production. As the nylon power well, parts come out with smooth surfaces and nice detail, needing little post-processing. This reduces labor costs and accelerates delivery. At Whale-Stone, we have observed also that with SLS nylon printing there is less waste as unused powder often can be circulated back into new prints. This is also better for the environment and brings down material costs. It also makes production lines more flexible. When demand shifts, we can easily adjust our batch sizes printing more or fewer parts without extra setup. Parts printed in SLS nylon can sometimes substitute for metal parts so products are lighter and easier to assemble. This enables customers to save on shipping and handling. From what we’ve seen, SLS nylon technology not only accelerates the job but also provides a more flexible and cost-effective manufacturing process which is exactly where many companies are today.

Where To Get Affordable SLS Nylon Parts For High Volume Production Runs

If you have a large number of robust and detailed plastic parts, Nylon 3D printing is an excellent option. SLS is short for Selective Laser Sintering. It’s a unique mode of 3D printing that employs a laser to heat nylon powder into solid shapes. That yields parts that are tough, flexible and useful in the real world not as mere models or prototypes. If you need a lot of these parts, it is essential to have access to low-cost SLS nylon printing. At Whale-Stone, we know how to do that. We use smart machines and talented workers to print multiple parts at a time without sacrificing quality. That should keep the price per part down, which is good for businesses that need to buy in bulk. Plus, we take advantage of the same kind of powerful yet inexpensive nylon powder. This trade-off is what helps keep prices low, yet makes sure that every piece is built tough and reliable. When you’re looking to order large amounts, shop for a company like Whale-Stone, which can process big orders without a hitch. Good companies will also assist your order planning enough to make sure you get your parts on time. They can recommend the appropriate designs for printing, so that the pieces come out right and end up not being wasted. This way, you pay less and get more. In the end, if you want inexpensive SLS nylon parts that can be useful for many things, select a company with experience, good equipment and smart planning like Whale-Stone. We ensure your production parts are strong, cheap and there when you need them.

What SLS Nylon End-Use Parts Mean for Wholesale Buyers

Your customer is also a wholesale buyer, like yourself, and could be an individual or a company who wishes to buy a large quantity of parts at once to include them in their own project, sell them to someone. These are some of the main lessons that you can learn as a wholesaler trying to buy SLS nylon end-use parts. First, end-use parts show that the part has been finished and is now ready to be incorporated in the finished products and not test pieces. SLS nylon is fine to this kind of stuff it is very tough and can withstand a beating. We are ensuring that at Whale-Stone all is fitted in high quality before they reach your hands and hands of your customers. Second, part design might affect print. Simple shapes are less expensive to print and print faster, however, at times you desire a more complicated geometry. In Whale-Stone, we assist you in finding the best construction design that has a good cost and yet sound footing. Third, there are color, finish. When nylon is printed, the natural colors are white or gray; it can be dyed and painted also after its printing. What you want to look at or feel, talk to us at the beginning of the day and we can properly organize it. Fourth, there is the delivery time. You will have plenty of parts when you are purchasing wholesale now. Whale-Stone has its strong points in terms of the arrangement of production time in order to release your orders on time yet without compromising the quality. Last but not least, ask about testing and certification. Since these components are covered in final goods, you would like to find out that they are safe and dependable. Whale-Stone prepares specific reports and is able to conduct other tests, in case of necessity. Know these facts to assist wholesale buyers to make a smart choice on SLS nylon end-use components. Whale-Stone will assist you, starting with your ideas of design right to delivery.

How To Solve Common Problems With Sls Nylon Production For Wholesale Markets

The manufacturing of SLS nylon parts to the wholesale markets has some challenges to be realized. However, by knowing the common problems and their solutions, it is possible to make everything run smoothly. One usual issue is warping. Components are capable of bending or twisting due to heating and cooling of the nylon powder within a short period of time. We have special machines at Whale-Stone which very carefully regulate temperature as we are 3-D printing. Parts of ribbing, cooling structure or shape change are also engineered by us to avoid warp. The other issue is surface roughness. The powder causes some SLS parts to be grainy or rough. To overcome that, Whale-Stone also offers post-processing services of sanding or polishing parts in such a manner so as not to be rough but to be in usable condition. And portions could contain little holes or weak points. It achieves this when the laser does not entirely melt the powder every time everywhere. Our technicians are always checking on the machines, and we turn the laser power and laser speed to provide a solid and strong part to every job. Uniformity is all in a large order. Components must be the same in all batches in terms of looks as well as performance. Whale-Stone uses after and during printing controls. Before we deliver them to you we measure, test strength, and examine details. Communication is key too. Should a problem arise, our professionals collaborate with you to ensure an optimum solution is obtained expeditiously. These are the kinds of problems that Whale-Stone will not only be aware of, but it also knows how to fix them; hence, peace of mind by the Whale-Stone buyers. The components are robust, smooth and just right to your products however many you require.

Table of Contents

- Reasons Why We Love SLS Nylon For Custom Wholesale Printing

- How SLS Nylon Technology is Making Manufacturing End-Use Parts More Efficient

- Where To Get Affordable SLS Nylon Parts For High Volume Production Runs

- What SLS Nylon End-Use Parts Mean for Wholesale Buyers

- How To Solve Common Problems With Sls Nylon Production For Wholesale Markets