Designing something new can be a little like being trapped in a tiny box. You have good ideas but fret that you don’t know how to bring them about. And this is where SLS nylon printing from Whale- Stone has flung the door wide open. It enables you to produce highly detailed forms or complex geometry and functional parts with little to no restriction. Because of how things were made, you don’t have to concern yourself with complex molds or breaking your design. Instead, you can let your thoughts run wild and take shape in 3D. It's not only fast, it allows you to make things that were either impossible or prohibitively expensive previously. You realize that here in SLS nylon, you’re starting to see how unbound your creativity is from old rules

Why is SLS Nylon printing well suited for complex design prototyping

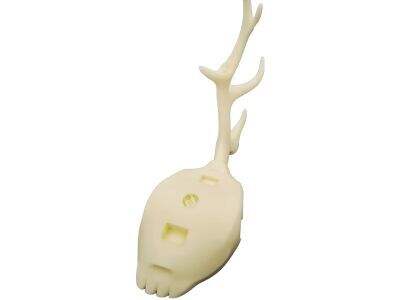

If you’re a maker or entrepreneur who wants to fabricate prototypes or try out new product ideas, the printer will need to be capable of producing challenging shapes and tiny details. Making these out of SLS nylon is the best because it uses a laser to selectively melt nylon powder one layer at a time. This doesn’t require any supports, unlike some printers, and you can design very complex shapes with holes or curves or even moving parts inside without extra work. For instance, a small tooth gear or hollow part may be fabricated in a single piece. Plus, nylon is strong and pliable so your prototype won’t shatter easily when you try it out. "It's such an 'ah-ha' moment that it seems to astonish our clients," says Whale-Stone, "because their complex designs emerge so rapidly and the printed parts are very close to what they intend as a final product." A customer once wanted a prototype with thin walls and complex patterns for a drone part. The other methods either did not work or would have taken weeks. Thanks to SLS nylon printing we had a beautiful part in our hands within days that did everything promised. The ability to experiment freely with designs at no waiting cost and little financial cost revolutionizes the way ideas are developed. If you have any sharp edges, undercuts or complex shapes your design can handle it all and not leave your ideas in pieces

SLS Nylon Printing For Your Wholesale Production: The Ultimate Q&A Guide

Building one of something is cool, but building lots of them that all look and function the same is harder. SLS nylon printing excels here as well and particularly with Whale-Stone’s precise process. Service Fanatics The technology relies on powder that can be recycled, which reduces waste as well as costs. And because the laser fuses the nylon powder uniformly, all parts have a consistent strength and finish. Now multiply that by 100, if you want to make a hundred pieces of a custom phone case or those mechanical parts, every fifth one should be identical. We’ve had to develop unique processes both for preparing the powder, controlling the printing environment and dealing with parts after they are printed to make sure quality remains high. Occasionally, little things occur like pinholes or rough areas, and our crew know how to fix or prevent them before they even become an issue. Such an attention to detail means you receive quality parts that your own customers can trust. Also, for large orders speed of production is a factor. SLS nylon printing makes it possible to print parts in a single batch, which saves both time and money. At Whale-Stone we combine tradition with technology to achieve fast, efficient and smooth runs. This makes SLS nylon printing a sweet spot NOT just for making designs real, but with confidence taking it to market. If you’re looking to build your business with clean, durable and accurate parts, this is a clever way to go

Overcoming Design Limitations when Developing Products with SLS Nylon Printing

When people innovate new products, they encounter innumerable design problems. Old ways of making things, whether it’s molding or cutting, can restrict what we are able to build. These techniques occasionally must have plain or simple shape design, because tooling cannot handle complex parts. Enter SLS nylon printing, a unique way of creating things using a powder called — you guessed it — nylon. What I mean by SLS Nylon printing At Whale-Stone, we print SLS nylon to help designers and inventors go beyond these ancient limitations. In this type of printing, a laser melts nylon powder layer by layer to create an object. Because it builds up layer by layer, it can make very detailed and complex shapes that are difficult or impossible to produce with other means. For instance, parts with micro-holes inside, in tunnels or on moving joints can all be fabricated collectively without assembling pieces separately afterward. That means designers can be more creative in their thinking, without having to worry about whether their ideas are too complicated to manufacture

One of the other huge drawbacks to the old ways is that they can be slow and costly when you want to experiment with new designs. It costs a tremendous amount of money and effort to switch out one mold or tool for another. But when it comes to SLS nylon printing, you will only require a digital file to begin printing. So, if you’d like to revise your design, the process becomes refresh the file and print again. That speeds up and lowers the cost of product development, which allows for more trials and better results. Plus nylon is a strong, flexible material, so the printed parts are durable for a variety of applications. This enables designers to make actual parts that work, not mere models. At Whale-Stone, we guide our customers to leverage SLS nylon 3D printing, to have their product ideas realized without being bound by old rules

How SLS Nylon Printing Offers Wholesale Products Fast Iteration and Design Freedom

If businesses hope to sell products in bulk, they must be confident that the design is right. But it takes a lot of tries to find the perfect design. This is what’s known as iteration — you make little changes again and again in order to make something better. In traditional manufacturing this can be time consuming and expensive because each change could require new tools or molds. But SLS nylon printing it makes prototype multiple versions that much more feasible. We use this at Whale-Stone to help companies accelerate their design process. Since it requires only a computer file for printing, companies can print one or just a few samples quickly, check them and then alter the design without incurring additional expense on molds or tools

And since there’s virtually no cost to this rapid iteration, designers can see how a product will feel, work and look before they commit to making a batch in the hundreds of thousands or millions. They can solve problems, make things more comfortable or introduce new features, fast. Additionally, the SLS nylon printing process allows for very complex designs that include moving parts married together or shapes which drive out weight but retain strength. This freedom to design also ensures wholesale-led products can be more innovative and tailored for the customers. Another benefit is that small lots or customized types are easy to produce without interrupting production. This suits companies very well who wish to test different markets or product customization. At Whale-Stone, we even show our customers how to leverage SLS nylon printing to get rapid and flexible development for growth without all the expense and slow downs of traditional methods

The Most SLS Nylon Printing Problems And Solutions dequeueReusableCell

There are a lot of benefits to SLS nylon printing, but it’s not without its challenges that need to be managed. At Whale-Stone, we hope to help customers solve some common problems, and make their printing experience smooth and successful. A common problem is warping, when the printed part curls or twists as it cools. This has the potential to destroy its shape and ruin your part. Parts should have even thickness and need to avoid sharp corners to prevent warping. And carefully controlling the temperature at which something is printed and its cooling afterward can help keep parts stable

Another possible problem is surface roughness. SLS prints are also typically a bit grainy as a result of the nylon powder. This texture is occasionally not desired, particularly for regions that are required to have a very smooth finish and fit perfectly with other parts. This can be addressed with post processing such as sanding, polishing or coating. At Whale-Stone, we offer our customer the most cost-effective solutions for surface finishing to enhance the appearance and texture of your parts

In some occasions, parts can have little holes or weakness when the laser settings are not well placed or also if part is too thin on certain areas. Ensuring the design has sufficient thickness and the right printing parameters is important. Our typographers at Whale-Stone will also be reviewing design before you printed to identify these things early on. Finally, it’s worth noting that SLS nylon printing is most effective for some types of products. The really big stuff would cost a lot, and some things can’t be printed with SLS. Understanding these limitations can help customers better plan projects

Awareness of these three areas printing and how to address them will allow SLS nylon printer users to reap all the benefits Nylon printing has to offer no sweat! Whale-Stone is dedicated to ensuring that every part of this journey can easily be achieved, enabling designers and businesses to take full advantage of their creative freedom when utilizing SLS nylon printing

Table of Contents

- Why is SLS Nylon printing well suited for complex design prototyping

- SLS Nylon Printing For Your Wholesale Production: The Ultimate Q&A Guide

- Overcoming Design Limitations when Developing Products with SLS Nylon Printing

- How SLS Nylon Printing Offers Wholesale Products Fast Iteration and Design Freedom

- The Most SLS Nylon Printing Problems And Solutions dequeueReusableCell