In 3D printing, there are multiple techniques that can be used. Two of the most employed techniques are Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). These technologies may seem similar, but there are nuances that significantly affect the way they make parts. It’s important to understand the variance in order to consider investing in additive manufacturing technology such as SLM or DMLS.

Both SLM and DMLS are additive manufacturing processes which direct a laser source to produce solid three-dimensional (3D) metal parts from powdered material. But the difference here is that the metal powders are melted and fused together. SLM melts the metal powders entirely to form a dense and uniform part while DMLS partially melts and agglomerates the metal powders in more or less of a granular structure. SLS 3D Print Service is another option for 3D printing.

Material properties SLM generates components with better densities and mechanical strength than DMLS in general. Thanks to the complete melting of the metal powder in SLM process material particles are strongly bound which means a longer life span of the parts. In contrast, part densities and mechanical properties of DMLS may be inferior because the metal powders are, at most only partially melted or in granular form. SLS 3D Print Service is another option for 3D printing.

One of the great distinctions that can be made between SLM and DMLS is the necessary post-processing steps. As SLM has parts with higher densities they may undertake less post sintering (heat treatment or HIPing (Hot Isostatic Pressing)) to enhance material quality. Here, in comparison DMLS parts will require more post processing steps, to get the desired mechanical properties and surface finish. SLA 3D Print Service is also a popular choice for 3D printing.

Whether you opt for SLM or DMLS When deciding between the two production methods, you need to consider criteria like part complexity and material selection as well as post-processing capability. SLM may be a more favorable method to produce high-strength and dense parts with intricate geometry than DMLS where the quality and time of benefits, however, for rapid prototyping or when exceptional mechanical property are not critical issues, DMLS could be an appropriate choice.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

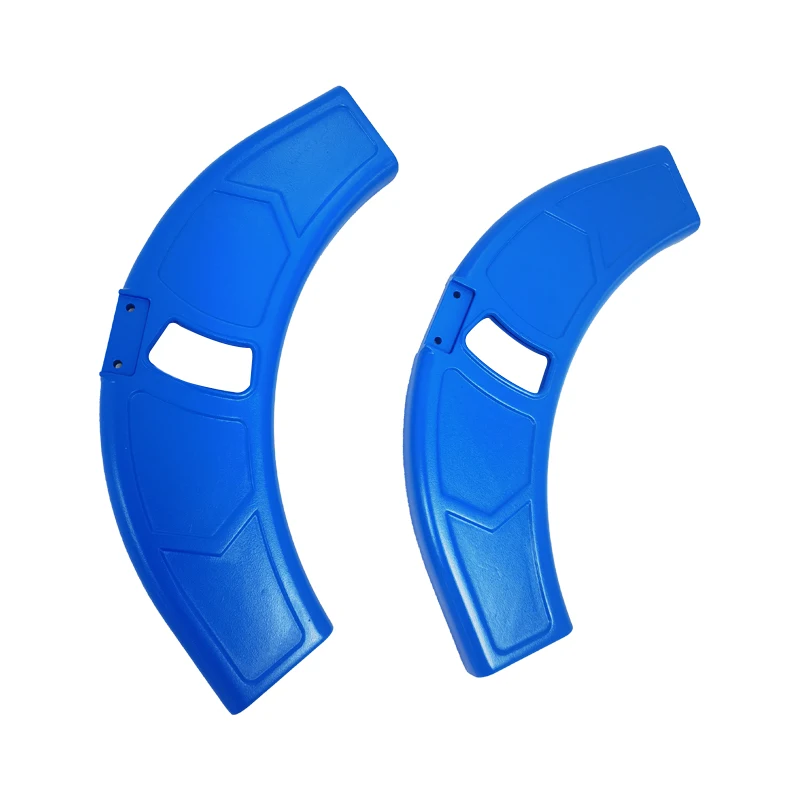

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.