At Whale-Stone, we keep ahead of the industry curve in construction by using the latest manufacturing techniques and high obsession with details. This is one of the innovative solutions that we have adopted, which is CNC Machining; a technology disrupting mass production in the industry.

Adherness We are dedicated to making the quality and innovation for industrial buyers available at wholesale pricing from Whale-Stone. With our Microfluidics 3D Printing, we can build complex parts with unparalleled precision and detail so that all of our products offer the highest quality and long term durability.

Hotend: WHALE-STONE through Microfluidics 3D Printing, simplifies the production process, saves time and cost of manufacturing. This leading edge technology allows us to fabricate sophisticated designs at unparalleled speeds and efficiency, which gives us a significant market advantage. Microfluidics 3D Printing

Augmenting the Potential of 3D Printing With its increased speed, 10x the detail resolution and quality compared to competitors at a fraction of their price. Vacuum Casting

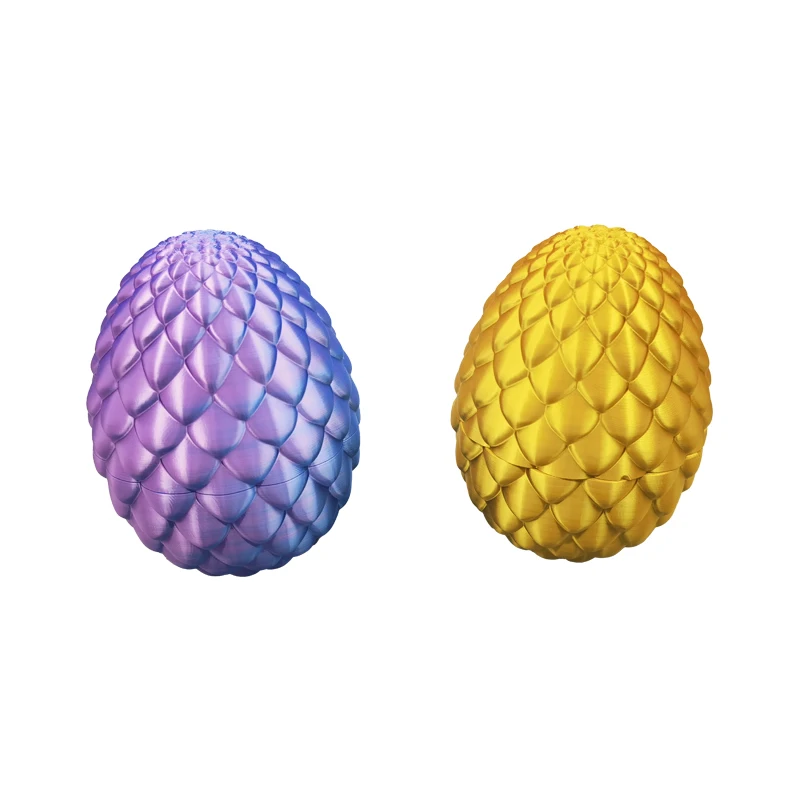

Unleashing Infinite Design Possibilities One of the main advantages of Microfluidics 3D Printing is it's freeing of design limitations. 'Here at Whale-Stone we know what an amazing impact creative design can have and using this cutting-edge technology, the most intricate designs are possible with both precision and efficiency.

It is our intention to bolster our production capacity and provide quality products to customers through this acquisition by way of Whale-Stone's high technology accuracy processing technologies. Focused on precision carved parts various jig and tool abrasive processing machinery, we can also take orders for high-accuracy machined components - stock removal machining service that secures us a great number of core companies. Our Microfluidics 3D Printing is the ultimate solution for fast, high-precision custom-designed products that conform to your exact production specifications and technical demands.

With dedicated automotive design and development capabilities, we support the entire vehicle development cycle from concept modeling and design verification to functional prototyping, tooling, fixtures, and small-batch production of both metal and non-metal components.

We emphasize fast response times with 24/7 online support, fast printing speeds, and stringent quality controls, enabling quick-turn prototyping, first-article customization, and efficient small-batch manufacturing.

We operate seven integrated technical centers—including SLA, SLS, SLM printing, rapid mold manufacturing, and CNC machining—providing a full spectrum of additive manufacturing solutions for automotive, industrial, and product development applications.

We offer a wide range of printing materials and provide both forward design and reverse engineering services, allowing for tailored material performance and complete design-to-production support for diverse industrial needs.