SLA 3D printing wouldn’t be where it is today without support structures. They're the ones doing the heavy lifting, in a sense, to bring those prints of yours into the world clean edges, crisp details, and long-lasting builds guaranteed. How Whale-Stone help in 3d resin printing SLA by strengthen support structure design? Below, you’ll learn more about why effective support structure design is key to success when it comes to 3D printing.

Support Structure Design: In Importance for good quality of high Resolution SLA 3D Prints

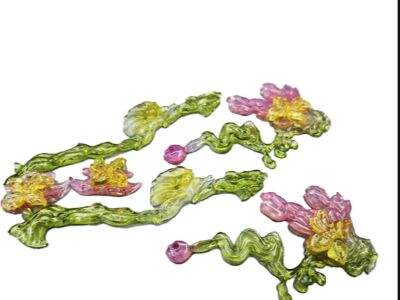

Supports are crucial for the success of nearly every 3D resin print in the SLA world. These support structures are created to hold parts of the model that would otherwise collapse or become deformed through printing, adding details and overhangs to models. At Whale-Stone, we really do obsess over the little things when creating support stands for our clients prints. Via personalized support structures that are designed for the particular geometry of each piece, we maintain ideal levels of stability and precision, creating finished products that meet or exceed expectations.

3D Printing to improve print accuracy and stability

In terms of getting high quality and stability in SLA 3D prints, the design of support structures is not something to be taken lightly. At Whale-Stone, we have developed a team of highly skilled technicians that use state of the art software and hardware to design and print support structures that optimize the overall quality of prints. Where we place our supports, how dense and thick they are will determine if we print successfully without warping it will directly affect print accuracy and stability. Our pursuit of superior 3d resin printing service ensures that we are at the forefront of the market.

Mesh Support structure set-up and settings for optimal print success ratios.

In the fast-paced realm of 3D printing, success rates are a leading indicator of service reliability and competence. At Whale-Stone we know the need for a high rate of success printing for our customers. With some advanced support structure design techniques, we can increase the probability of a successful print, and at the same time reducing our risk due to failed prints or bad quality results. Our customized support structure design for a higher quality print, every time ensures your prints will be perfect just like other satisfied customers who keep coming back.

Supporting Structures Designed To Efficiency: Less Waste More Printing

In today’s industrial manufacturing world, being efficient and minimizing waste is of paramount importance. Here at Whale-Stone we’re dedicated to reducing time inefficiency and waste through bespoke support structure design. By taking the time to critically evaluate these models and plan out support placement, we can minimize material use in each print, reduce print times, and in the end save our clients a lot money. Our strategic methods in aid with support structure design not only improve the entire printing process, but also lead to a more sustainable and environmentally friendly addend manufacturing.

Raising satisfaction customers with accurate Support Structure Design methods

At Whale-Stone, the customer’s needs are a priority. Our accurate design support structure methods are how we go above and beyond client expectations while providing superior outcomes. By leveraging our engineering and customer knowledge, we can develop support structures that improve the quality, accuracy and reliability of every print. We are a trusted partner and set the bar for high-quality, paradigm-shifting SLA 3D printing; delivering tangible value to our clients in prototype and production quantities on every successful print run with excellence as the standard.

All in all, the significance of support structure design within the context of an SLA 3D printing service could not over-emphasized. At Whale-Stone, we are committed to providing high quality prints which implemented effective support structure design strategies to improve precision, stability and efficiency. Our customer-focused approach and commitment to deliver quality sla 3d printing solutions for more sustainable production have helped us to benefit from high levels of repeat business.

Table of Contents

- Support Structure Design: In Importance for good quality of high Resolution SLA 3D Prints

- 3D Printing to improve print accuracy and stability

- Mesh Support structure set-up and settings for optimal print success ratios.

- Supporting Structures Designed To Efficiency: Less Waste More Printing

- Raising satisfaction customers with accurate Support Structure Design methods