Üretim dünyasında verimlilik ve kalite, bir şirketi rekabetten ayıran unsurlardır. Whale-Stone'da, üretim sürecinizi daha iyi hale getirmek için yeni teknolojileri nasıl kullanacağımızı biliyoruz. Parça ve ürün tasarımınızı dönüştürebilecek yepyeni bir çözüm sunuyoruz: 3D baskı . SLS 3D yazdırma, imalat sürecinize birçok avantaj sağlayabilir.

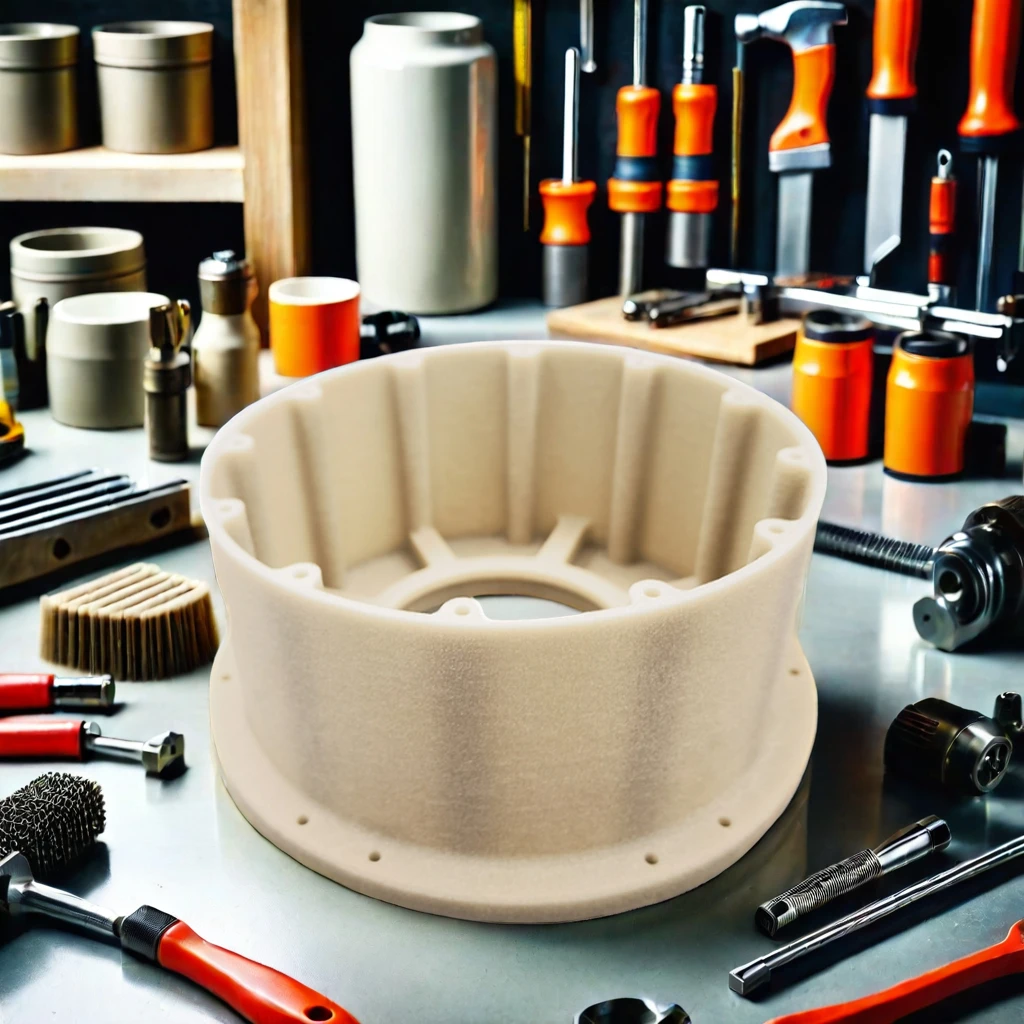

Tasarım özgürlüğü, SLS 3D baskının en büyük avantajlarından biridir. Geleneksel işleme ve imalat yöntemleri genellikle karmaşık geometrileri, süslü formları üretmede sınırlamalara sahiptir. 3D baskı mevcut tasarım sınırlamalarından kurtulmanızı ve daha önce elde edilemeyen sonuçlara ulaşmanızı sağlayan 3D baskı yüksek hassasiyet ve detay ile gerçekleştirebilirsiniz. Hakkında daha fazla bilgi edinin özel OEM 3D yazdırma hizmetleri .

Rekabetçi pazar ortamında dayanıklılık ve kullanılabilirlik ürünleriniz için oyunu değiştiren faktörler olabilir. SLS 3D baskılar birçok diğer üretim malzemesinden daha güçlü ve dayanıklıdır. Prototip, son kullanım parçaları veya üretim ekipmanları oluşturuyor olun, 3D baskı teknolojisi ürünlerinizin en iyi şekilde performans göstermesini ve görünmesini sağlar. Artırılmış ömür ve performans ile son kullanıcılarınıza daha yüksek maliyet verimliliği ve kalite sunarsınız.

İmalatta kalite ve hassasiyet sadece seçenekler değil, geleceğin işinizin temel göstergeleridir. Whale-Stone olarak kaliteli işçiliğe ve dikkatli detaylara inanıyoruz. Bizimle 3D baskı , ürettiğimiz her parça ve üründe mükemmel kalite ve doğruluktan yararlanın. En son teknoloji, yüksek teknolojili tesislerimiz ve birikim sayesinde her detay mükemmellikle özenle işlenir. Küçük parçalardan büyük yapılara kadar 3D baskı diğer süreçlerin sunabileceğinden daha üstün kalite ve hassasiyet sağlar.

Günümüzün hızlı tempolu ve aşırı rekabetçi piyasasında, iş başarısı için rakiplerin önünde olmak zorunludur. 3D baskı fark yaratmak mümkündür. Üretiminizi basitleştirerek ve yeni modelleri piyasaya sürerek öne çıkabilirsiniz. Whale-Stone'ı tedarikçiniz yaparsanız, pazarda rekabet avantajına, inovasyon ve kalite konusunda ise bir adım önde olmaya sahip olursunuz. Devrim niteliğinde olanı benimseyerek işinizi başarıya bir üst seviyeye taşıyın Sls nylon 3D baskı .

24/7 çevrimiçi destek, hızlı baskı hızları ve katı kalite kontrolleri ile hızlı yanıt sürelerine vurgu yaparak hızlı prototipleme, ilk makale özelleştirme ve verimli küçük parti üretimini mümkün kılar.

Otomotiv tasarım ve geliştirme konusunda özel kapasitelere sahip olarak, konsept modellemeden tasarım doğrulamaya, işlevsel prototiplemeden kalıp, sabitleyici üretme ve hem metal hem metal olmayan bileşenlerin küçük partilerde üretimine kadar tüm araç geliştirme döngüsünü destekliyoruz.

Çeşitli endüstriyel ihtiyaçlar için geniş bir baskı malzemesi yelpazesi sunuyoruz ve ileri tasarım ile tersine mühendislik hizmetleri sağlayarak, malzeme performansının uyarlanmasını ve üretimden tasarıma kadar tam destek sunuyoruz.

SLA, SLS, SLM baskı, hızlı kalıp üretimi ve CNC işleme dahil olmak üzere yedi entegre teknik merkez çalıştırıyoruz ve otomotiv, endüstriyel ve ürün geliştirme uygulamaları için tam bir eklemeli üretim çözüm yelpazesi sunuyoruz.