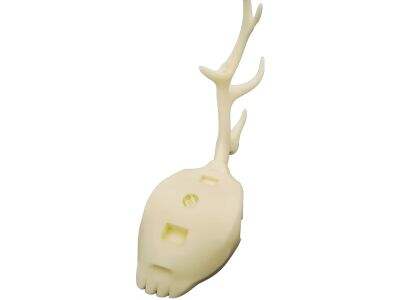

Sebuah kaedah pencetakan 3D yang popular, Selective Laser Sintering (SLS) menghasilkan komponen yang kuat dan terperinci. Tetapi sebaik sahaja selepas percetakan , bahagian-bahagian ini cenderung kasar dan berdebu. Fonetik Makmal dan Pascapemprosesan Untuk menjadikannya kelihatan menarik, serta berfungsi dengan baik, ia sudah memerlukan pascapemprosesan. Pascapemprosesan adalah proses yang menjadikan bahagian cetakan cukup baik untuk digunakan atau dijual, dengan membaiki, membersihkan, dan menyiapkannya. Cara anda boleh pascaproses cetakan SLS 3D anda Terdapat pelbagai cara untuk menyiapkan cetakan dari segi estetik dan fungsi supaya ia cukup licin dan kuat untuk hampir semua kegunaan. Perkhidmatan ini mungkin termasuk penggilapan, pewarnaan, pengekalan dan lain-lain. Setiap langkah dalam proses ini mengubah rupa, sentuhan, dan sering kali prestasi produk akhir. Memahami teknik pascapemprosesan yang tersedia kepada anda akan membantu anda mencapai hasil terbaik bagi cetakan SLS anda

Memilih Perkhidmatan Penyediaan yang Tepat untuk Percetakan 3D SLS Borong

Memilih langkah penyiapan akhir yang sesuai untuk cetakan 3D anda boleh menjadi sukar. Ia juga bergantung kepada bagaimana rupa bahagian akhir yang diinginkan, sama ada licin atau berwarna, dan sebagainya mengikut kehendak anda. Di Whale-Stone, kami akan bantu anda membuat keputusan tersebut dengan menganalisis penggunaan bahagian tersebut secara terperinci. Jika anda sedang mencipta komponen yang bertujuan sebagai alat berfungsi (seperti milik saya), ia mungkin memerlukan kekuatan lebih tinggi dan kurang hiasan. Namun, jika untuk tujuan pameran atau model, kelicinan dan warna lebih penting. Penggilapan, sebagai contoh, boleh menghilangkan tompok kasar pada objek tetapi boleh melemahkan komponen jika dilakukan secara berlebihan. Pewarnaan akan menukar warna, tetapi tidak akan membaiki kekasaran permukaan. Penyegelan boleh melindungi daripada air atau habuk tetapi menambahkan kilauan ringan, yang mungkin tidak diterima. Kadang kala, ini merupakan gabungan pelbagai pilihan. Anda mungkin mahukan hasil akhir yang lebih cepat tetapi kurang tepat untuk menjimatkan perbelanjaan bagi pesanan besar. Pesanan kecil boleh menerima kerja yang lebih teliti. Selain itu, pertimbangkan masa — sesetengah proses penyiapan memerlukan lebih banyak masa. Ia bukan sekadar memilih pilihan yang paling kurang buruk; ia adalah memilih apa yang paling sesuai dengan keperluan dan bajet anda. Kami di Whale-Stone memberi maklumat secara jujur supaya anda tidak perlu membayar untuk langkah-langkah tambahan yang tidak diperlukan. Kami juga menerangkan secara terperinci apa yang dilakukan oleh setiap jenis penyiapan, supaya anda tahu dengan tepat apa yang perlu dijangka. Kadang kala, orang membuat keputusan bahawa mereka sebenarnya tidak mahu sampel selepas semua ini, dan itu tidak mengapa. Kami ingin memastikan anda menerima apa yang diperlukan tanpa sebarang kejutan.

Jadi di manakah saya boleh mendapatkan pengeposan yang boleh dipercayai untuk pencetakan 3D SLS borong

Boleh jadi membingungkan untuk mencari tempat yang baik bagi menyelesaikan cetakan SLS 3D anda. Nuansa bahagian SLS tidak diketahui oleh semua bengkel pascapemprosesan. Di Whale-Stone, kami memberi tumpuan kepada memastikan setiap proses sepadan dengan piawaian cetakan anda. Kami bergantung kepada pekerja mahir dan mesin yang telah diuji untuk membersih, menghalus dan mewarnai bahagian dengan tepat. Sesetengah perniagaan mengambil jalan pintas atau menggunakan kaedah yang lebih rendah kualitinya yang boleh merosakkan bahagian atau menjadikannya kelihatan buruk. Kami tidak melakukan sedemikian. Kami begitu menghargai setiap bahagian seolah-olah ia milik sendiri. Selain itu, masa juga penting. Kami berusaha untuk tepat pada masanya tetapi kami tidak suka tergesa-gesa menyiapkan bahagian. Komunikasi juga penting. Kami sentiasa memberitahu anda, dan kami meminta pandangan anda sepanjang proses ini. Kami tahu apa yang boleh berlaku, dan kami tidak membiarkannya berlaku. Kami juga menguruskan pesanan besar dengan baik, jadi anda tidak akan mengalami sebarang kelewatan. Ramai pelanggan kami kembali kepada Whale-Stone kerana mereka percaya pada kami. Jika anda peduli bahagian anda kelihatan baik dan tahan lama, carilah perkhidmatan yang memahami kepentingan SLS di sini. Whale-Stone adalah tempatnya. Kami berusaha menjadikan cetakan anda sempurna sebaik sahaja keluar dari pencetak. Ini menjadikan produk anda lebih baik dan pelanggan anda lebih puas hati

Pengaruh pemprosesan pasca terhadap prestasi produk borong bercetak 3D SLS

Apabila anda menerima barang cetakan 3D yang dibuat menggunakan teknologi SLS (Selective Laser Sintering), proses tersebut tidak berakhir apabila pencetak berhenti mencetak. Pemprosesan pasca adalah langkah utama selepas pencetakan. Ia membantu menjadikan produk lebih kuat, licin dan lebih boleh digunakan. Bagi Whale-Stone, kami sedar bahawa pemprosesan pasca boleh mempengaruhi keberkesanan komponen cetakan 3D apabila anda membeli secara pukal, contohnya secara borong

Pertama, pemprosesan pasca boleh mengukuhkan komponen SLS. Laser SLS melebur serbuk, tetapi kadangkala wujud ruang kecil atau permukaan kasar. Ini boleh melemahkan atau merosakkan komponen tersebut. Whale-Stone boleh mengisi ruang-ruang ini dan meningkatkan ketumpatan bahan dengan merawatnya menggunakan proses khas seperti pemanasan atau mandian kimia. Inilah sebahagian daripada usaha untuk menjadikan komponen lebih tahan lama dan kekal utuh dalam persekitaran tekanan tinggi

Kedua, permukaan selepas proses pasca-pemprosesan adalah licin dan mudah dirawat. Selepas pencetakan SLS selesai, bahagian-bahagian kerap kelihatan seperti kapur atau kasar. Ini boleh menjadi masalah jika produk perlu muat dengan baik bersama komponen lain atau disentuh oleh manusia. Permukaan boleh diperhalus melalui rawatan pasca-pemprosesan, seperti penggilapan atau penumbukan. Ini merupakan kaedah-kaedah yang digunakan oleh Whale-Stone untuk menjadikan bahagian-bahagian terasa selesa dan kelihatan kemas, yang penting apabila anda mempunyai produk yang dijual dalam jumlah besar dan digunakan dalam kehidupan sebenar

Akhir sekali, teknik pasca-pemprosesan boleh memberikan ciri istimewa kepada komponen tersebut. Sebagai contoh, adalah mungkin untuk mengaplikasikan cat atau lapisan pelindung lain pada bahagian-bahagian tersebut bagi menjadikannya kalis air atau tahan kerosakan. Ini sangat berguna untuk produk borong yang boleh digunakan dalam pelbagai persekitaran. Di Whale-Stone, pasukan kami melaksanakan pelbagai pasca-pemprosesan secara terpilih untuk memenuhi keperluan setiap produk. Ini memastikan komponen berfungsi dengan baik, supaya anda mendapat nilai terbaik untuk wang anda

Ringkasnya, pasca-pemprosesan bukan sahaja untuk menjadikan bahagian kelihatan baik. Ia juga merupakan faktor utama dalam prestasi bahagian dan tempoh ketahanannya. Cetakan 3D SLS berkualiti tinggi perkhidmatan Cetakan di Whale-Stone menguruskan butiran halus ini untuk memastikan pelanggan menerima bahagian yang kuat, licin, dan boleh dipercayai setiap kali mereka membeli secara pukal

Apakah teknik penyelesaian terbaik untuk komponen cetakan 3D SLS borong peribadi

Apabila anda mencari komponen tersuai pencetakan 3D SLS dengan kuantiti besar, pemilihan kaedah penyelesaian adalah perkara penting. Di Whale-Stone, kami menyediakan pelbagai teknik penyelesaian yang boleh anda pilih untuk memastikan komponen tersuai anda kelihatan dan berprestasi dengan baik. Setiap jenis penyelesaian mempunyai kelebihannya tersendiri, dan pilihan yang sesuai bergantung pada aplikasi, bentuk, dan rupa yang diingini bagi komponen tersebut

Terdapat beberapa kaedah penyelesaian biasa, contohnya penggilapan. Ini menghilangkan terbur dan menanggalkan tepi tajam daripada komponen. Bagi komponen yang boleh anda gilap sendiri, penggilapan adalah sangat baik kerana anda boleh berhati-hati dalam mengekalkan bentuk dan butiran yang diingini. Whale-Stone menggunakan mesin khas dan penggilapan secara manual untuk memastikan setiap komponen keluar dengan permukaan licin tetapi masih muat dengan ketat

Perolengan atau penggilapan juga digunakan dengan kerap. Ia melibatkan penempatan komponen ke dalam mesin bersama batu-batu kecil atau biji-bijian yang menggesel permukaannya. Ini akan meratakan permukaan secara sekata dan memberikan kilauan yang cantik. Perolengan sangat sesuai untuk pesanan borong jenis ini kerana ia mampu memproses kuantiti besar sekaligus, menjimatkan masa dan kos, sambil menghasilkan komponen yang kelihatan bersih dan profesional

Pengecatan dan salutan juga merupakan pilihan yang baik untuk komponen suai khas. Setelah dikikir rata, tangkal tentakel boleh dicat atau diwarnakan oleh Whale-Stone mengikut spesifikasi anda. Kami boleh menambah lapisan bening untuk menahan calar dan kesan air. Lapisan sedemikian menjadikan produk tempahan lebih menarik dan tahan lama, yang penting apabila menjual secara borong

Namun, untuk sebahagian bahagian, rawatan khas adalah yang terbaik: pengecatan atau penghalusan wap. Proses pengecatan memasukkan warna jauh ke dalam bahan manakala penghalusan wap menggunakan bahan kimia untuk meleburkan permukaan sedikit bagi memberikan rupa yang berkilat. Teknik-teknik ini berkesan jika anda mahukan kemasan berkilat tanpa perlu menggilap atau jika bahagian-bahagian tersebut agak rumit

Kami tahu setiap pesanan tersuai adalah unik di Whale-Stone. Oleh itu, kami membantu anda memilih proses kemasan yang betul untuk bahagian-bahagian anda. Dengan cara ini, anda menerima bahagian pencetakan 3D SLS borong tersuai yang tidak sahaja dipersonalkan oleh anda tetapi juga dikemasankan secara sempurna untuk memenuhi jangkaan anda

Cara Mendapatkan Kemasan yang Konsisten dalam Pemprosesan Pasca Percetakan 3D SLS Borong

Jika anda membina komponen SLS 3D berskala besar daripada perkhidmatan seperti Whale-Stone, adalah penting bahawa semua komponen tersebut mempunyai kualiti tinggi yang tidak dapat dinafikan. Kualiti seragam bermakna setiap komponen kelihatan dan berfungsi sama seperti komponen lain. Ini terutamanya penting untuk pesanan borong, kerana perubahan kecil boleh menyebabkan isu besar. Untuk memastikan kualiti yang konsisten, Whale-Stone melaksanakan langkah-langkah pemprosesan pasca yang teliti

Pertama, kami menggunakan kawalan kualiti yang ketat sebelum, semasa, dan selepas pemprosesan pasca. Sebelum anda mula üKami memeriksa komponen kami untuk kualiti cetakan dan kecacatan. Dalam pemprosesan pasca, pekerja menjalankan langkah kerja yang sama seperti penggilapan, penggiliran atau salutan dengan cara yang seragam. Ini memastikan setiap komponen dirawat secara sama dan tiba pada tahap kehalusan dan kekuatan yang sama

Kedua, Whale-Stone memiliki mesin canggih yang boleh memproses berbagai komponen serentak tetapi masih berfungsi secara sekata pada kesemuanya. Sebagai contoh, mesin guling boleh dicondongkan pada sudut yang betul, dijalankan cukup lama dan pada kelajuan yang sesuai untuk mengelakkan penggilapan berlebihan atau tompok kasar. Pasukan kami sentiasa memantau mesin-mesin ini dan melaraskan tetapan jika perlu untuk mengekalkan kekonsistenan serta kualiti penyelesaian yang tepat setiap kali

Kami mendidik staf kami untuk menghargai kepentingan kekonsistenan. Semua individu yang terlibat dalam pemprosesan pasca mengikuti arahan yang jelas dan menggunakan peralatan yang sesuai. Jika sebarang komponen tidak memenuhi piawaian kualiti tinggi, ia akan dibaiki atau dibuang sebelum penghantaran. Penjagaan teliti ini membantu Whale-Stone memastikan hanya produk terbaik dan terbaru sampai kepada pelanggan kami

Akhirnya, satu log semua langkah dan ujian pasca-pemprosesan diselenggara. Ini membolehkan kami memantau kualiti setiap pesanan dan mengenal pasti kawasan yang perlu diperbaiki. Whale-Stone boleh dengan mudah menyemak rekod dan menerangkan apa sahaja yang sedang dilakukan jika anda mempunyai sebarang soalan mengenai komponen anda

Secara ringkasnya, bergantung pada kualiti tinggi dalam borong SLS 3D percetakan terletak pada pemeriksaan menyeluruh, penggunaan mesin yang tepat, profesionalisme manusia dan kebolehlacakkan. Pasca-pemprosesan kualiti Whale-Stone bermaksud setiap komponen yang anda pesan adalah licin dan kuat, sedia untuk digunakan supaya anda boleh yakin terhadap produk bercetak 3D borong yang diterima

Jadual Kandungan

- Memilih Perkhidmatan Penyediaan yang Tepat untuk Percetakan 3D SLS Borong

- Jadi di manakah saya boleh mendapatkan pengeposan yang boleh dipercayai untuk pencetakan 3D SLS borong

- Pengaruh pemprosesan pasca terhadap prestasi produk borong bercetak 3D SLS

- Apakah teknik penyelesaian terbaik untuk komponen cetakan 3D SLS borong peribadi

- Cara Mendapatkan Kemasan yang Konsisten dalam Pemprosesan Pasca Percetakan 3D SLS Borong