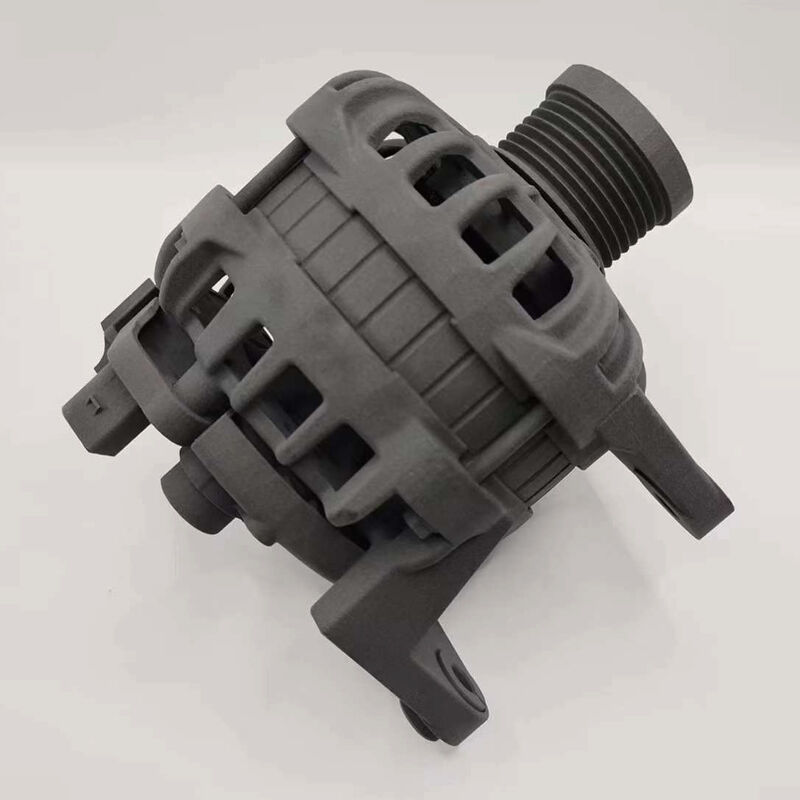

GF nylon is a kind of special material that add glass fibers in the molten nylon to become strong and very great abrasive resistant. This is an important concept in robotics because robots can operate under hard conditions. They must be able to tolerate stress, impacts and other demands without breaking. At Whale-Stone, we know how important stiff and durable casings are in robotics. Our GF nylon equipment is perfect for all the robotic applications, making sure that the machinery can perform in most of the conditions. With materials such as this, robots have the potential to perform better and last longer, a win for all parties involved

Best places to order good quality GF Nylon for robotics applications

So finding good quality GF nylon for robotics is key. Of course, you will want to ensure the material you select is reliable and durable. Whale-Stone is a really good place to involve because we specialize in making tough materials that are suitable for robot industries. Our GF nylon is manufactured using the latest in manufacturing techniques to ensure that it has the perfect balance of stiffness and longevity. You can employ it for a variety of robotics, from tiny drones to huge industrial machines. If you're in search for GF nylon, look to suppliers of industrial commodities. They tend to have more variety and can assist you in choosing the best one for your project. It’s also nice to have samples in hand before you make a purchase, so that you can feel the quality yourself. With Whale-Stone, you can rest easy knowing that you’re getting materials that are designed to last. And we also deliver great customer service to help you choose which option is perfect for you. Our team is at your disposal to answer any questions and assist you in choosing the right floor. You can also seek out trade shows or industry events at which companies such as Whale-Stone feature their wares. This means that you can see your materials in person and speak to specialists who can explain the advantages of GF nylon for robotics

Why Opt for GF Nylon in Robotics Casings

GF nylon is the preference for robotic casings for a few reasons. First, it’s stiff enough to maintain its structure even under pressure. Robots on the move can expect bumps and jolts. The casing can bend or break, if it’s not sturdy enough. With GF nylon, you can sleep easy knowing that the case will shield your sensitive components inside. That helps the robots operate smoothly, without interruption. Second, GF nylon is really durable. It is resistant to wear — a crucial consideration for robotics in rugged environments. For instance, if a robot is being used in a factory that has dust, oil and other elements, you casing needs to be strong enough to sustain these. GF nylon does just that. And, it’s lightweight which is a huge plus. Robots have to move fast, and heavy materials can weigh them down. With GF nylon, developers can design lightweight shells that are also strong. Finally, GF nylon is also inexpensive. It’s durable, so parts don’t need to be replaced frequently, which will save you money in the long run. Here at Whale-Stone we believe that GF nylon is intelligent decision and serves all these purposes. Whether your are creating a small robot or large automation system we have been accustomed to serving customers in the mechanical automation industry. Tough and light weight, you can count on GF nylon to help your robotics projects with its long history of success

The Generic Problems Of Using GF Nylon In Robotics And How To Beat Them

GF nylon (glass filled nylon) is a heavy and stiff material which is commonly used in robotics. This material is created by incorporating small glass fibers into nylon, which makes it much stronger than standard nylon. GF nylon is great and all, but there are several issues people typically encounter when incorporating it for robotics. One problem is that GF nylon can also be more brittle than some plastics. That means it could snap or splinter if you hit it hard, or stress it a lot. To avoid this, designers can try to minimize sharp edges in their designs so parts don’t weaken and crack. Another issue is that GF nylon can actually be heavier than conventional nylon in some instances. That can be a problem for robots that are required to be light and fast. Robot makers could address this by using thinner parts, or adding other — lighter — materials to the GF nylon mix to lighten it further. Last but not the least, GF nylon can occasionally absorb moisture, which may alter its size and strength. One solution for designers to address this is through the use of special coatings or treatments which prevent moisture from entering. Understanding these universal problems, and addressing them are ways Whale-Stone can make better and more reliable robots using GF nylon

What GF Nylon’s Benefits Are for Wholesale Buyers

GF nylon is a good option for bulk buyers who are buying materials for robotics. One of its most valuable attributes is its strength. GF nylon can take a beating and be extremely weight bearing with out breaking, so it works perfect for robot parts that need to be tough. On top of that, its stiffness allows robots to hold their shape and function properly even in rough conditions. For these reasons, robots built with GF nylon can perform better and last longer. It also has the additional benefit of GF nylon and resistance to many chemicals so it won’t easily get damaged in various environments. That’s important for robots that could see service in factories or other locations where they could be exposed to oils and the like. Wholesale purchasers should also be aware that GF nylon is capable of being formed into a wide variety of shadow shapes. This versatility can be exploited for innovative design leading to more sophisticated and efficient robots. At Whale-Stone, we think it’s important to share some of these benefits with our wholesale customers so that they can make informed decisions when choosing materials for their robotics project

Long-term protection for robotics casings with GF Nylon

There are some procedures to be followed which will ensure a long life of robotics casings made from GF nylon. The Text First, its important to pick the right GF nylon. There are a range of strength and flexibility between GF nylon grades, so choosing the best one for the specific application is paramount. Next, proper design is crucial. Engineers should concentrate on designing to balance can't stress loadings around the casing. It helps to eliminate weak spots that may strike or fail. Casing Durability Testing Test, of course, is a critical part of it if we’re making claims about the durability of GF nylon casings. Before deploying them on actual robots, prototypes should be tested to learn how they perform under stress or impact. This testing can uncover any vulnerabilities that have to be remedied. Last but not the least is frequent servicing to maintain the robotics casings in its best form. They can last for many years with routine maintenance, such as checking for wear and tear, cleaning them and adding protective coatings. Here at Whale-Stone, we also like to suggest these measures for all GF nylon users, if requested robotics casings that are strong and sturdy