Implantes médicos feitos de liga de titânio utilizando a fusão seletiva a laser (SLM) representam uma forma especial. É um método de alta tecnologia que utilizamos na Whale-Stone para criar implantes camada por camada, de modo que um implante possa ser ajustado perfeitamente ao corpo de cada paciente individualmente. Em vez de cortar ou moldar metal a partir de um bloco grande, o SLM funde pequenas quantidades de pó metálico com energia proveniente de um laser para atingir exatamente a forma desejada. Isso tornaria possível criar dispositivos resistentes, leves e com superfícies que ajudam o corpo a aceitá-los.

Fusão seletiva a laser sobre biocompatibilidade e comportamento celular em implantes

O segredo está na forma como a SLM fabrica cada camada minúscula dos implantes. Ao fundir uma liga de titânio em pó com um laser, a Whale-Stone pode criar formas muito mais elaboradas do que pelos métodos tradicionais. Isso nos permite criar poros pequenos e superfícies rugosas no implante, o que auxilia o crescimento de células ósseas dentro dele. Quando o osso cresce nesses orifícios, o implante fica mais firmemente ancorado no corpo, reduzindo a probabilidade de se mover ou soltar. E como o implante é projetado sob medida para se ajustar ao paciente, ele distribui as forças no corpo de maneira mais uniforme.

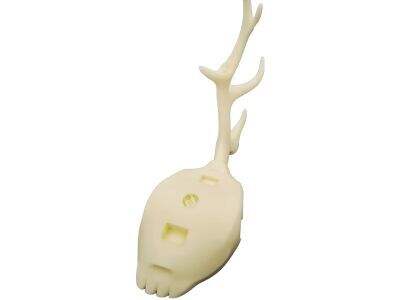

Impressão SLM de implante de liga de titânio médico

Imprimindo com peças personalizadas em nylon o pó metálico derreter demais. Se o laser ficar muito quente, o metal pode deformar ou rachar. Pouco calor pode resultar em camadas que não aderem bem, tornando o implante frágil. Na Whale-Stone, gastamos bastante tempo ajustando as configurações exatas ideais do laser. Depois, há o próprio pó. Ele precisa ser realmente puro e deve ter o tamanho adequado.

Garantia na impressão SLM por atacado de implantes médicos

Se você está imprimindo em 3D implantes médicos com equipamento médico impresso em 3D implantes precisam ser seguros e bem ajustados dentro do corpo. Temos muitas etapas para garantir que nosso implante de liga de titânio seja perfeito. Primeiro, começamos com matérias-primas da mais alta qualidade. Estamos utilizando pó de titânio 100 por cento puro e o titânio que imprimimos é rigorosamente testado antes da impressão. Isso evita problemas durante a impressão.

Compre liga de titânio personalizada SLM de qualidade

Compradores por atacado interessados em implantes de liga de titânio personalizados de alta qualidade fabricados por serviço de impressão 3d online por exemplo, podem encontrar fornecedores confiáveis como a Whale-Stone. É muito importante comprar diretamente de uma empresa que saiba como produzir implantes com cuidado. A Whale-Stone fornece implantes específicos para fábrica, garantindo procedimentos de implantação precisos que incorporam tecnologia SLM de ponta.

Implantes Médicos Personalizados de Titânio

Muitos aspectos tornam a Fusão Seletiva a Laser um método preferido para fabricar implantes médicos personalizados de titânio. Na Whale-Stone, preferimos utilizar o SLM, pois nos ajuda a criar implantes resistentes e precisos que se adaptam virtualmente ao corpo de cada paciente com a possibilidade de personalização no design. A maior vantagem do SLM é que ele constrói o implante camada por camada a partir de centenas de pequenas partículas de pó de titânio, permitindo à Whale-Stone produzir formas mais complexas, difíceis de serem obtidas com outros métodos. Dessa forma, os implantes podem ter orifícios especiais, superfícies rugosas que ajudam os ossos a crescerem dentro do implante, tornando-os mais eficazes.